Instrumentation

Coanda is constantly acquiring, optimizing, and developing new measurement techniques for application to single phase flows, multi-phase flows (gas-liquid, gas-solid, liquid-solid and gas-liquid-solid), as well as non-Newtonian single and multi-phase flows. Some of the key measurement technologies available at Coanda include:

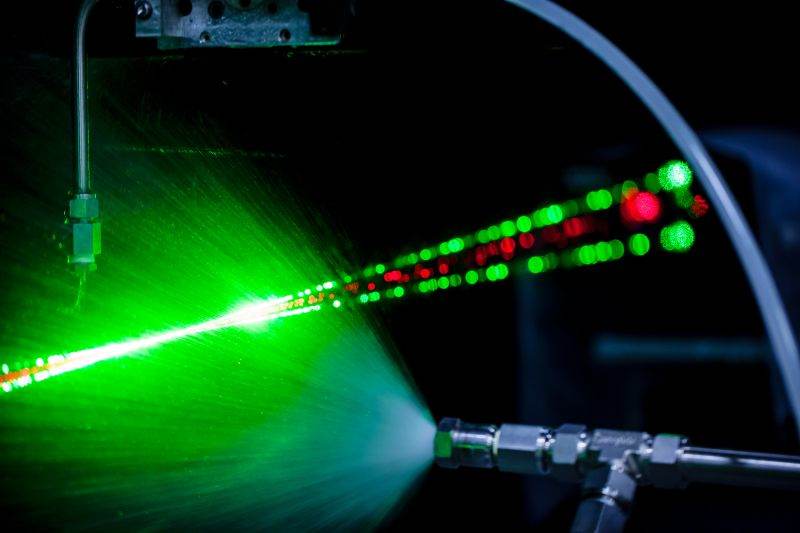

Phase Doppler Interferometer (PDI)

Coanda’s PDI system (Artium Technologies) is capable of measuring droplet size, volumetric flux, and two components of velocity. This technology is able to perform reliable and accurate characterizations of spray nozzles and aerosol dynamics.

Phase Doppler Interferometer (PDI) measurement of spray nozzle

Constant Temperature Anemometry (CTA)

Also referred to as Hot Wire Anemometry, this system is used for measurement of one, two or three velocity components in either gas or liquid applications. In comparison to an LDV system, a CTA system can acquire data at a much higher rate.

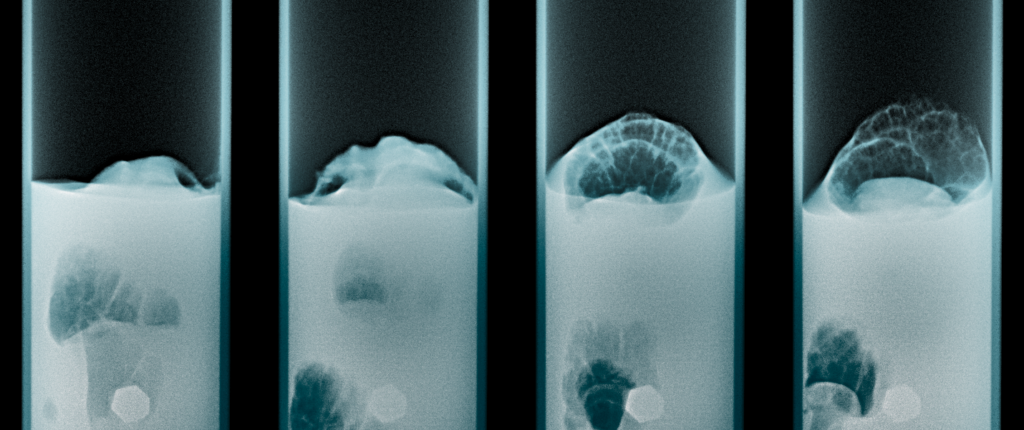

X-Ray Imaging

Coanda has 3 x-ray imaging systems, covering a wide range of imaging needs, as well as experience constructing custom shielding enclosures around our process models in order to capture large numbers of images during regular operation:

- A fast (50 ns) x-ray system for catching process models “in the act”, even at high velocity. It has a fixed energy of 150 kVp and a 3 mm spot size. Good for imaging fast processes with good contrast, such as solid-gas nozzle sprays or fluidized beds.

- A modified medical system with 1.2mm spot size and selectable energy from 40-100 kVp. Good for imaging objects or processes up to similar thickness and density as the human body.

- An industrial system set up with extensive collimation (limiting secondary

scattering) and mounted on highly accurate traverses in order to create an image by slowly scanning a 1D detector and “fan” of radiation. This has allowed us to visualise as little as 3 mm zeolite thickness loss through 10 cm of steel. Selectable 0.4 mm or 1 mm spot sizes can be run at 100% duty cycle up to 320 kVp.

X-Ray – gas bubbles break the surface in a column of fluidized sand

Nuclear Densitometry

Coanda offers the capability of leveraging nuclear density gauges to measure fluid density in-situ, in pipes or in vessels. Coanda is licensed by the Canadian Nuclear Safety Commission for the use of “fixed” nuclear density gauges. We have experience using such devices both in the standard application measuring the density of a fluid/slurry stream, as well as traversing the source and detector together, or alternatively the entire process vessel, in order to measure gas/liquid distributions within opaque systems.

Particle Size Distribution

Coanda can offer both mechanical and optical particle size distribution measurements. Coanda employs three main optical techniques for particle sizing.

-

Laser Diffraction: Coanda owns two Malvern Instruments Mastersizer 3000 particle sizers for optical measurements. These instruments use Mie scattering theory and a distribution of high-sensitivity photodetectors to convert a laser diffraction pattern into a particle size distribution. Laser diffraction is appropriate for particles that can be diluted without destruction of the particles and works for particles ranging from 10 nm to 3.5 mm.

- Focused Beam Reflectance Method (FBRM): The Mettler-Toledo FBRM passes a diffraction-limited, tightly focused laser beam along the interface between the instrument window and the material under study. When the beam passes over a particle in the material light is reflected and the duration of the flash corresponds to the laser path length across the sample, or chord length. The particle size distribution (PSD) is calculated from the chord length distribution (CLD). Unlike laser diffraction, FBRM can be used in situ and works even if the material under study is essentially opaque. FBRM is appropriate for particles 500 nm to 2000 μm.

- Particle Vision Microscopy (PVM): Our Mettler-Toledo PVM provides complementary information to the FBRM. While sensitive to similarly-sized particles as the FBRM, the PVM provides complete images, unlike the other methods with compute a PSD. While the PVM provides a much richer data set than either FBRM or laser diffraction using that information in real-time process optimization requires development of machine-vision algorithms.

With a thorough understanding of the capabilities and limitations of each particle sizing technique, Coanda can implement the right technique for your process, correctly interpret the results and even develop machine vision algorithms.

Residence Time Distribution (RTD) Measurements

Coanda has a extensive experience performing RTD measurements and analysis on lab systems as well as field systems. Please refer to the RTD Measurements Technical Note for more information.

Multi-phase Sampling Techniques

We have developed various measurement techniques to quantify gas/liquid/solid holdup, evaluation of bubble size and velocity, and pressure fluctuations.

1-D Laser Induced Fluorescence (LIF)

A flow visualization technique providing qualitative and quantitative scalar field concentration measurements along a one dimensional line (4000 lps progressive scan, 2048 pixels at 12bits).

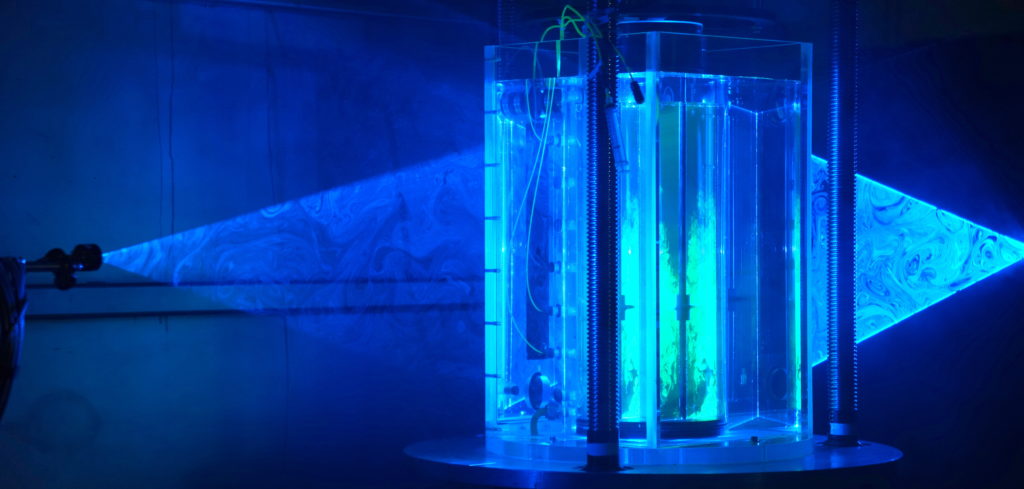

2-D Laser Induced Fluorescence (LIF)

A flow visualization technique providing qualitative and quantitative scalar field concentration measurements on a two dimensional plane (30 fps progressive scan, 800×600 pixels at 8bits).

Laser Induced Fluorescence (LIF) measurement of a mixing reactor

Fast Response Conductivity Probes

Using salt solution as a tracer, our fast response conductivity probes provide a high resolution point measurement of concentration. Up to 32 of these probes can be used simultaneously in situations where LIF techniques are not viable.