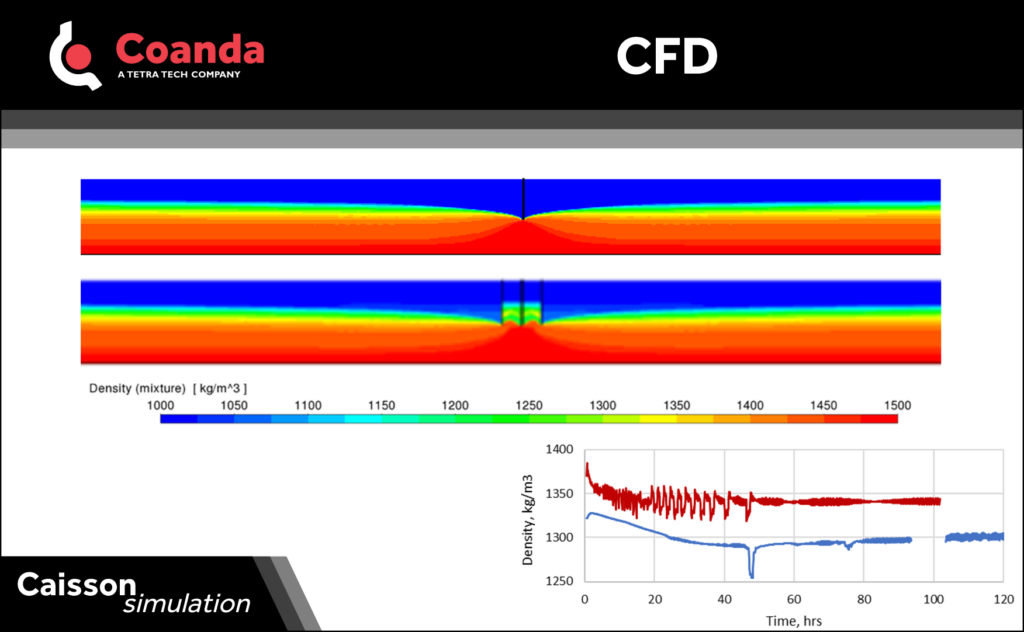

CFD – Caisson Simulation

Posted on October 16, 2024 Computational Fluid Dynamics

Management of fluid fine tailings (FFT) in oil sands operations requires harvesting it from tailings ponds via dredge pumps followed by chemical/mechanical treatment. One of the challenges during harvesting is cone formation between the clear water layer and tailings, which adversely affects the density of FFT and its consistent delivery to the tailings processing facilities. The coning occurs due to the non-Newtonian nature of the FFT material. Currently, the main mitigation strategy is to move the dredge from time to time to a different location outside of the developed cone. However, such interventions are costly and necessitate frequent process interruptions. Decreasing the frequency of dredge moves can reduce costs and streamline the withdrawal process. Therefore, improving the ability to withdraw denser material and develop a shallower cone can be very beneficial.

Recently, Coanda completed an IOSI (Institute for Oil Sand Innovation) funded study to investigate the use of a caisson—a large diameter cylinder placed coaxially around the dredge pipe—to mitigate the coning phenomenon. This is accomplished by increasing the effective dredge diameter and, therefore, the amount of slurry material withdrawn prior to significant density decrease. The study combined rheological experiments of aged material (to quantify the thixotropic nature of FFT), along with the development of a mathematical thixotropy model coupled with CFD flow simulations. In addition, small-scale withdrawal tests were conducted in Coanda’s lab to validate the comprehensive model, and finally, the model was applied to commercial tailing ponds to evaluate the advantages of a caisson.

As can be seen from the graph, dredging with the caisson results in higher density of the withdrawn slurry but the variability of the material increases, evidenced by density fluctuations, particularly during the first 50 hours of the withdrawal process. The density distribution contour plots highlight the profile changes inside the caisson as the denser slurry reaches the dredge from under the caisson without engaging less dense material. Outside of the caisson, however, the density profiles are very similar.