CFD Modeling Wood Drying Coupled with Airflow in a Kiln

Posted on January 16, 2023 Computational Fluid Dynamics Pulp & Paper

This post was originally published in two parts which have been combined below.

Part 1

Wood kilns are designed to remove moisture from lumber by means of supplied heat to evaporate liquid, which then is carried away by air circulation. Kiln drying is influenced by heat and mass transfer between the airflow and wood as well as by the complex moisture transport processes happening inside each piece of lumber. The physical nature of the process involves heat and mass transfer inside and outside of the lumber. While they can be studied independently, the full drying description can not be obtained without considering the coupling between the airflow and wood drying. For example, even in a perfectly designed kiln with a uniform air distribution throughout the wood and utilizing a perfect drying schedule, there still would be a difference in the drying rate between the board in front of the package and the one at the back, as the moisture and temperature of the air change with the passage over wood boards.

Kiln designers and operators face the difficult task of balancing product quality with a demand for the reduction of drying time. When limited experimental data is available, it is quite natural that mathematical modelling becomes an integral part of the research and design processes.

In our next post we’ll discuss the development of a suitable CFD model for kiln drying and present some model results.

Part 2

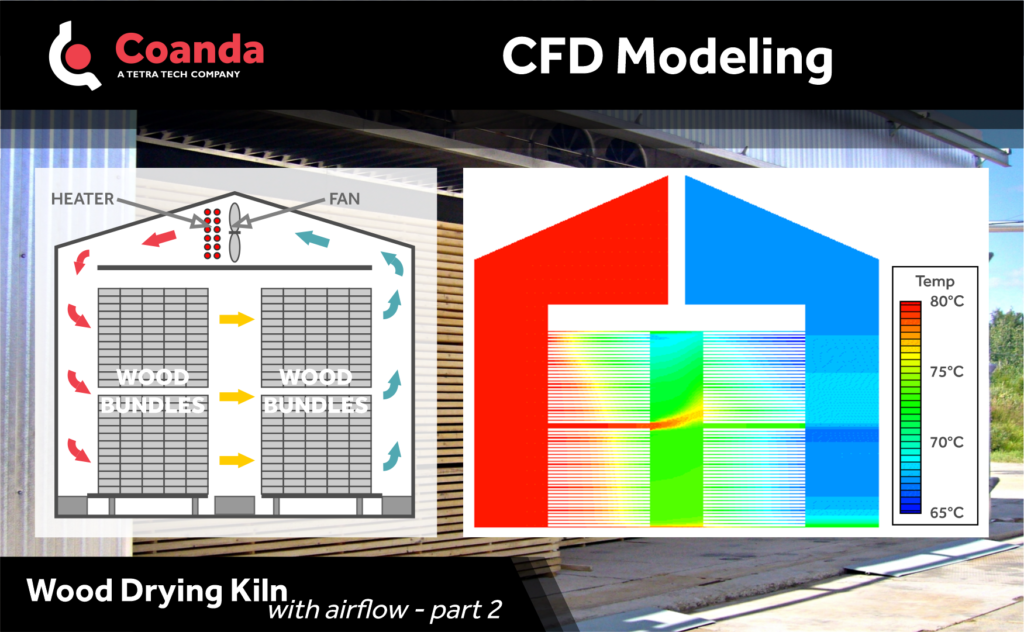

In our previous post, we introduced the challenges of kiln drying and determined that CFD modeling could benefit the research and design process. To facilitate this, a CFD model was developed of the airflow in a kiln that includes heat and moisture transfer coupled with the heat and moisture transport model inside the individual lumber pieces, which are treated as porous media with anisotropic permeability.

As can be seen from the contour plot, the temperature distribution inside the kiln is far from uniform: there are variations along the height of the lumber stacks and along the width of the kiln. This non-uniformity is connected to the drying non-uniformity of lumber shown on the graphs as the moisture content varies depending on the position of the board in the stack.

The computational kiln model can be an important tool for the design of new kilns, the analysis of problems encountered in existing kilns, and optimisation of operation. Computational methods can considerably reduce costly experimental time and increase the understanding of drying processes by allowing researchers to look inside the kiln and “inside” the wood piece when a kiln is in operation. Kiln performance can be analysed by changing initial conditions and drying schedules, reversing the airflow, implementing different control sequences, varying positions of control sensors and by trying many other alternatives. Model results can be incorporated into kiln control systems—providing relationships between process conditions, measured at various kiln locations, and important kiln performance parameters.