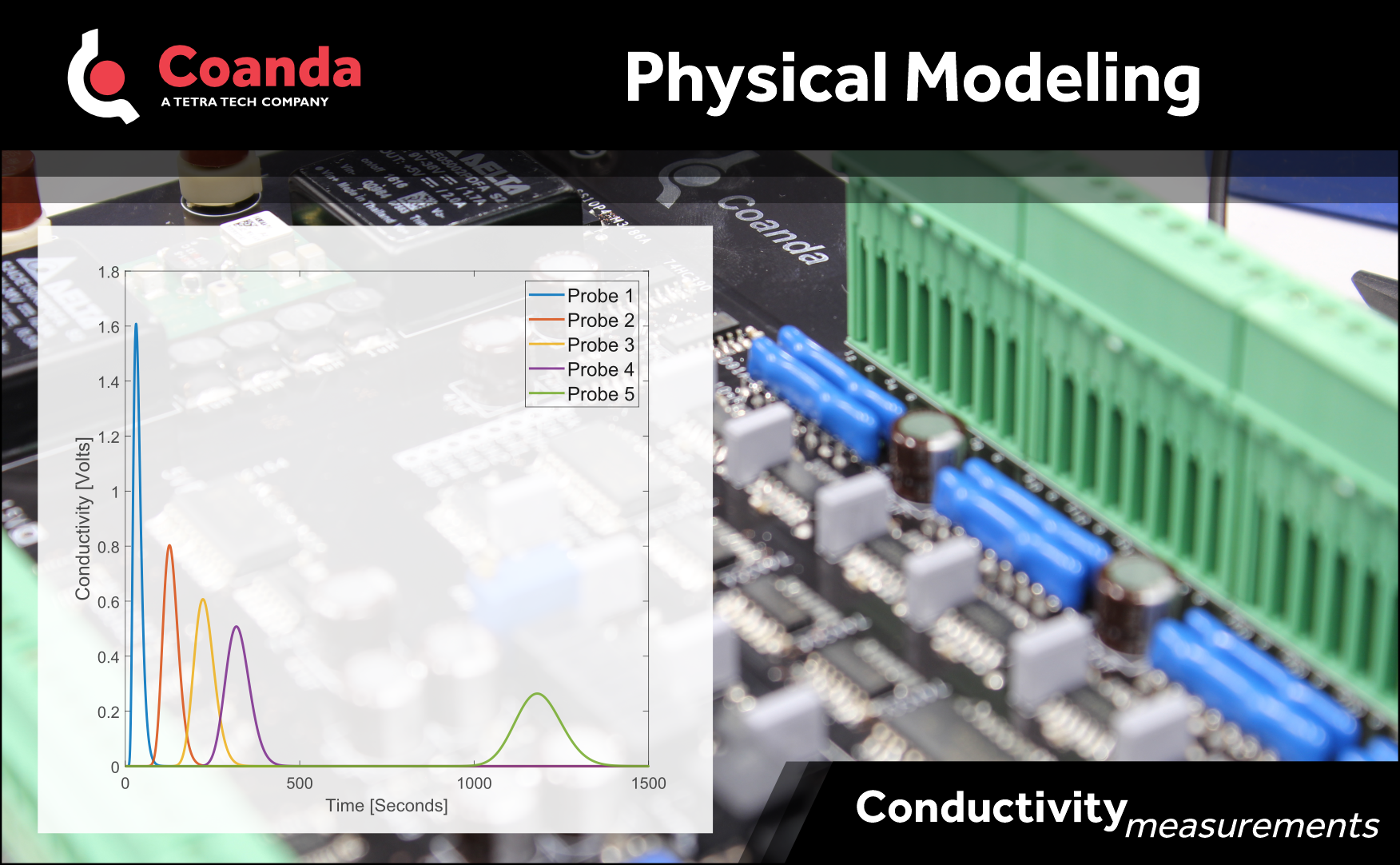

Conductivity Measurements

Posted on January 23, 2024 Physical Modeling

Gas-liquid flow regimes in feed piping can have a large influence on process performance. One of the main challenges in their design is that flow regimes show distinct and different behaviours that depend on several parameters, including gas and liquid flow rates, fluid properties, and piping geometry.

For example, liquid may flow as a stratified layer with or without the presence of droplets, or as an annular layer along the walls with fast-moving droplets in the core for relatively high gas volume fractions. For lower gas volume fractions, the liquid can still flow as a stratified layer with a smaller quantity of gas in the upper region of the pipe, or with dispersed bubbles distributed within the liquid layer, or both.

Multiphase flow regimes can be characterized by experimental techniques such as flow visualization and laser-based measurements. However, in many situations the liquid is not transparent, or the flow conditions are too harsh, such as high temperatures or pressures, preventing easy optical access. In such instances liquid conductivity measurements may be used instead.

Coanda’s custom-built multichannel conductivity instruments can use up to 32 probes installed at various locations within an apparatus. The measurements are performed by injecting a small volume of salt solution into the liquid flow (pulse), or by continuously injecting the salt solution at a location (step). Small needle probes (small enough to only minimally disturb the flow) detect the changes in conductivity signals over time, allowing for the measurement of breakthrough times and residence time distributions (RTDs) in the stratified or annular liquid phases near the walls. The presence of droplets in the flow can also be verified by the conductivity signal of any droplets that contact the needles. The resulting data is essential for characterizing reactor performance including utilization and mixing characteristics, potential short-circuiting or bypassing, by providing quantitative information on liquid residence times, which can also be used to identify flow regime features.