Cleantech is bigger than you think…

While ‘cleantech’ often conjures up images of wind turbines and solar panels, the term ‘cleantech’ actually considers all technology that lessens the environmental impact associated with energy production.

The aim of cleantech is to reduce the impact of energy production on air, land, and water, along with the associated ecosystems they support.

As a result, cleantech applications are broad, with examples in all of the conventional energy sectors. Examples of cleantech include advanced instrumentation for the detection of small releases of greenhouse gases, data science models for optimization of energy consumption in conventional energy plants, and microbiology that has been engineered to remove pollutants from water used during energy production.

The cleantech industry faces a number of technical challenges. Each specific challenge requires a tailored approach, which may include any combination of scaled physical models, mathematical modeling, process conceptualization and screening, computational fluid mechanics, instrumentation development, or analytical chemistry.

Dr Wayne Brown – VP Innovation

Our long-running expertise in these disciplines has led to significant advances in the commercialization efforts of many cleantech innovators, successfully supporting companies in a variety of ways:

- Scale up their existing offerings

- Help ongoing development of their products

- Achieve their energy efficiency intents

- Work towards sustainable use of resources

- Target their commercialization efforts

Past projects have included conventional abiotic and biological platforms, focusing on retrofits to existing infrastructure, or enabling of new technology. We have helped recent clients achieve measurable results in biofuel integration, CO2 sequestering, and energy efficiency.

Carbon Capture and Storage

Carbon capture and storage (CCS) involves:

- ‘Capturing’ carbon dioxide (CO2) in as concentrated a form as possible

- Transporting the concentrated stream to the point of sequestering

- Depositing the CO2-laden stream into a storage site where it will not be allowed to re-enter the atmosphere

Direct Air Capture

Carbon capture technologies generally target industrial waste streams, contacting them with liquids or solids that selectively remove CO2 from process gas.

Direct Air Capture (DAC) is a specific approach to carbon capture that removes CO2 directly from the air. Transport to the storage location typically occurs via pipeline, where the concentrated CO2 is often injected into deep geological formations that have the appropriate characteristics. Other approaches to storage involve forming carbonate salts or using the CO2 as a food source for algae.

Clean Energy

Cleantech also includes innovations to facilitate the transition from conventional fuels to non-conventional sources that have less of a negative impact on the environment. These include technologies for processing renewable feedstocks, and for the valorisation of waste plastics, to name a few.

Whereas conventional fuel processing, such as the refining of fossil fuels, have centuries of operating history, these new cleantech processes have very little, if any, time on stream. As the initial technical challenges associated with cleantech process flowsheets and unit designs are overcome, a suite of new ones are encountered as these novel processes are commissioned and come online.

Given the lack of experience with the issues encountered, the root cause must be uncovered as the first step to finding a solution. With no historical starting point to rely upon, a first-principles approach is required to unpack these problems.

Biofuels

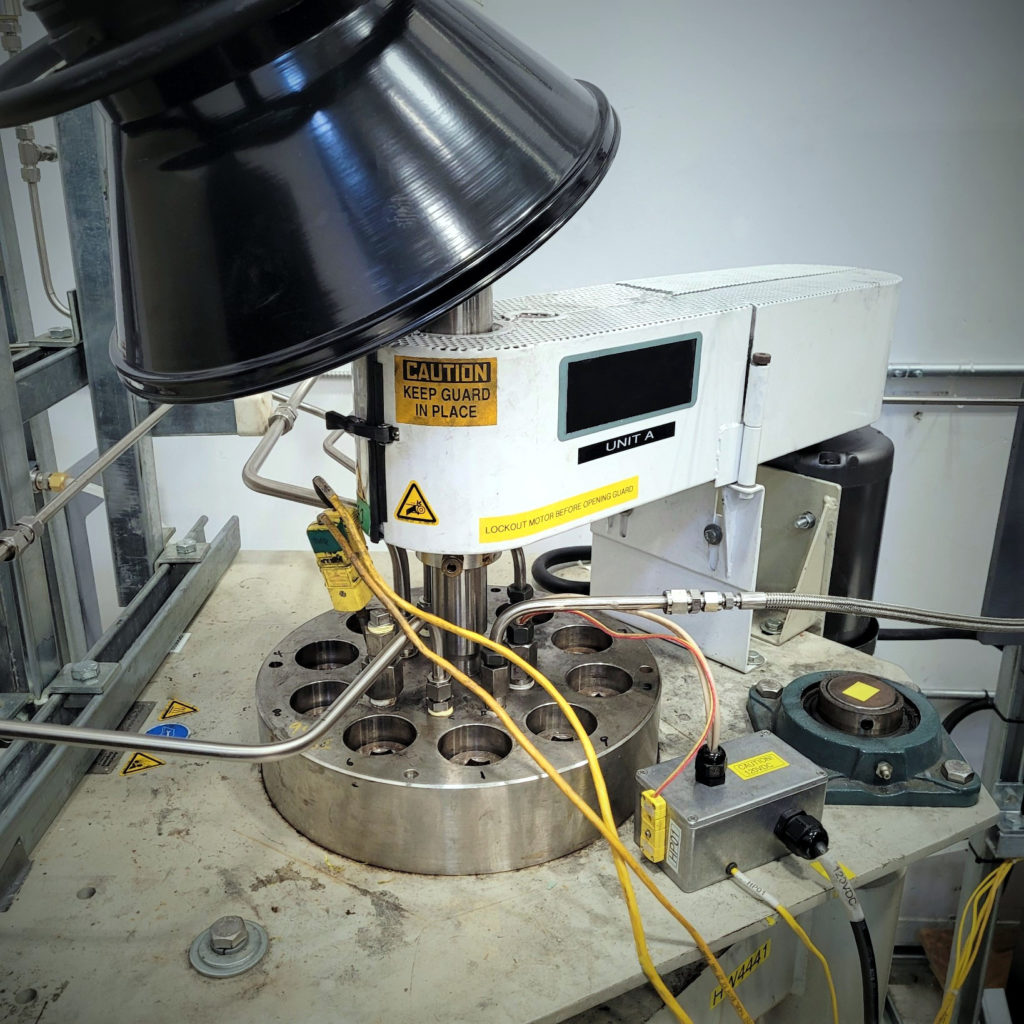

autoclave for biofuel integration testing

Biofuels are fuels derived from living matter or biomass. Examples of biofuels include biodiesel and ethanol. Plant based biofuels come from renewable sources and have lower carbon emissions compared to fossil fuels, on a life cycle basis. However, some sources can be quite expensive to produce, with large quantities of water required in some cases. The ultimate goal is to rely on biomass which is not fungible as a food source for human consumption.

The efficient production of biofuels is critical to their growth in our economy. Coanda’s capabilities and expertise in process engineering, complex fluid flow analysis and process scale up are well suited to support our clients with the development, optimization and implementation of new and existing process in the production of Biofuels.

In recent years Coanda has been working with clients on the many challenges associated with integrating biomass feedstocks into the existing energy infrastructure. Our scientists and engineers are well versed in the areas of chemistry, biology, engineering, and physics governing that must be tackled in decarbonizing the liquid fuel mix.

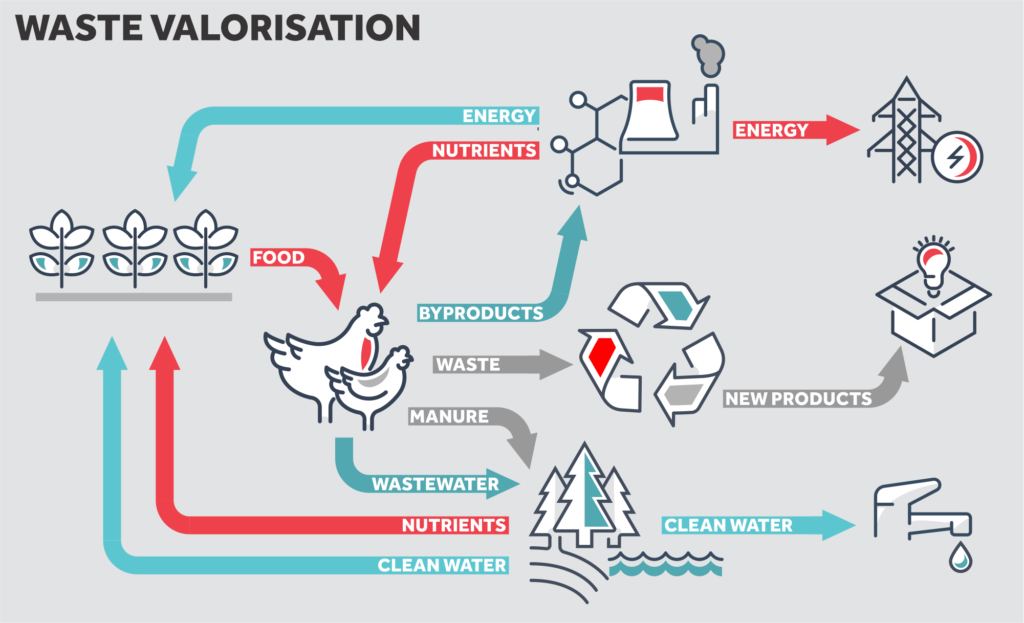

Waste Valorisation

In many instances, the process of valorisation—the industrial processes aimed at deriving energy or useful products from waste materials—has the potential to lessen the impact on the environment, on a life cycle basis.

From a scientific perspective, waste valorisation almost inevitably involves the reconfiguration of the molecular bonds in the waste material, producing either higher-valued products that are repurposed, or converting the chemical energy stored in the bonds into another form that can then be used to do work. Examples of waste valorisation are diverse, with many different approaches used to achieve the desired molecular re-arrangement. In some cases, biological catalysts are used, such as in the production of ethanol from pulp and paper waste. In another approach, fuel can be produced from waste plastics through pyrolysis.

Lithium Recovery

As the world shifts from its dependence upon fossil fuels, the demand for energy dense batteries continues to grow.

Lithium, a key component in these batteries is mined only in a small number of regions in the world. Producers are collectively challenged to meet the growing demand.

Ironically, the industry that is being most impacted by this transition in the energy sphere also provides a solution to this problem. During the production of conventional oil and gas, water is also brought to the surface. This water stream can contain appreciable amounts of dissolved lithium.

A number of cleantech companies have taken on the challenge of recovering this waterborne lithium by applying various technologies including:

- solvent extraction

- ion exchange

- solid phase adsorption

- selective precipitation

- membrane filtration

Despite several of these approaches proving very successful, there remain engineering challenges that must be overcome to become cost competitive.