Enhancing Interactions

Fluidized beds are common in industries such as petrochemicals, polymerization, pharmaceuticals, and power generation to name a few. Fluidization is one of the most effective ways of enhancing the interaction between the gas/liquid and the bed of solids, and is therefore used in operations where good mixing, superior contacting and mass transfer rates, and a uniform temperature distribution are important.

Fluidized bed dryers, reactors, scrubbers, and combustors, are known for their robustness to feed properties, relative simplicity in geometric configuration and scalability.

transparent fluidized bed model

1/9 scale cold flow fluidized bed model

Suspended Particles

Solid beds containing particles such as powdered coal, catalyst particulates, wood pellets, and polymer resin, can be transformed into a state resembling a fluid (hence fluidized bed) by suspending them in the upwards flow of a gas or liquid. In the absence of gas or liquid flow, the solids are initially in a fixed bed state.

As the flow of gas or liquid is gradually increased through the fixed bed, the solid particles eventually become suspended by the upward flow of gas or liquid, at which point the frictional drag force on the particles within the bed begins to overcome the weight of the bed.

Once a bed of solids is in a fluidized state, the two phase mixture of particulate solids and gas or liquid starts behaving like a fluid, and the pressure drop across any section of the bed is equal to the weight of the solid suspension in that section.

circulating fluidized bed with UV particle tracing

Fluidization Capabilities at Coanda

Our physical modelling laboratory is home to several fluidized beds, ranging from four inch diameter bubbling columns designed for rudimentary solids characterization, to 40 inch diameter by 32 foot tall circulating cold flow models that are geometrically similar scaled versions of commercial reactors.

Our approach to fluidization projects typically begins with a literature review, followed by a dimensional analysis to determine the most effective approach to the development of a solution, including physical models, computational modelling, or analytical techniques.

When a physical model is selected as the best recourse, the model is engineered to ensure a good match on similitude between the model and the commercial vessel. Cold flow models are typically constructed from a combination of steel and acrylic materials, or glass if optical access is required at elevated pressure.

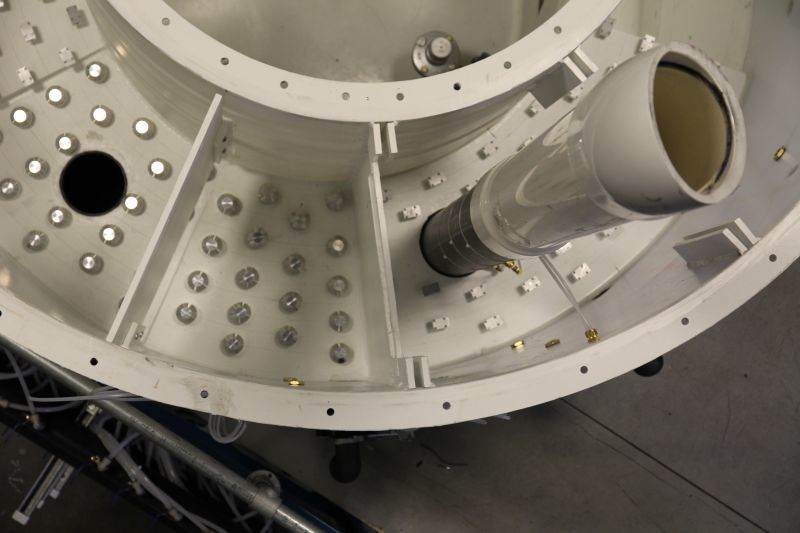

circulating fluidized bed gridplate details

Coanda’s supporting infrastructure includes a variety of pumps and blowers: two 150 horsepower blowers, a 270 horsepower compressor, and various pumps ranging from 3 – 50 horsepower. Coanda’s instrumentation and measurement capabilities include in-house built phosphorescent solids tracer and fast response helium gas tracer detectors, nuclear densitometers, and bed voidage measurement probes that detect changes in capacitance.

For more information on our fluidization capabilities, see our fluidization brochure.