Efficiency Advantages

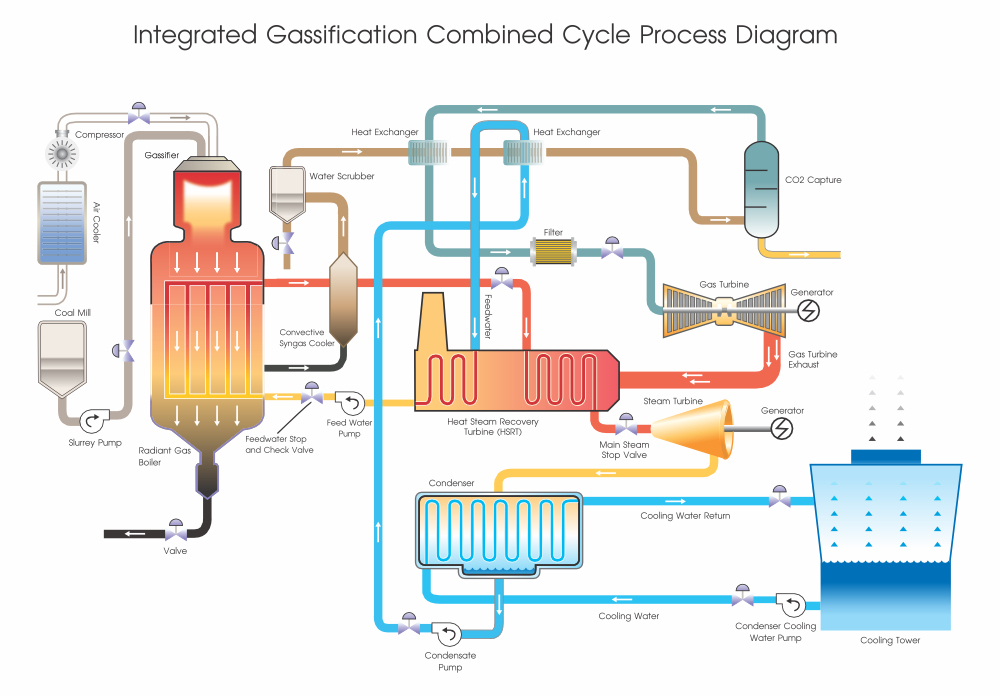

Gasification is a process by which coal or biomass and steam are converted into more commercially valuable commodities, such as hydrogen, methane, cleaner-burning liquid fuels, and chemicals used in production of fertilizer.

When used for electric power production in an Integrated Gasification Combined Cycle (IGCC), gasification offers the advantages of higher cycle efficiency, and, with carbon-capture, lower greenhouse-gas emissions, compared to pulverized-coal steam-cycle generators.

Operational Challenges

Despite its advantages, gasification remains a poorly-exploited technology, due to high capital and operating costs, particularly compared to pulverized coal and natural gas generators, and the current low cost of natural gas.

To gain market acceptance, capital and operating costs must be must be reduced by reducing the size and complexity of gasification equipment while improving efficiency and reliability.

Coanda is meeting these challenges by helping our clients to understand complex three-dimensional, multiphase, and reacting flows present in gasifiers.

Atomization Performance

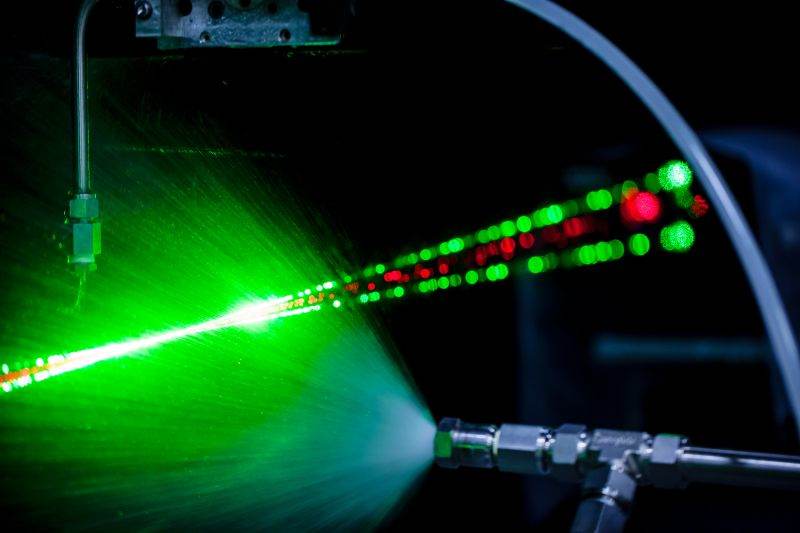

A full syngas quench requires not only adequate coolant flow but sufficient surface area for heat transfer. Thus, understanding the atomization performance and spray pattern of quench nozzles is an important first step toward optimizing the size of the quench tube in a gasification plant.

Coanda uses advanced measurement techniques, including phase-Doppler interferometry, to measure droplet size, velocity, and flux distributions produced by a wide variety of spray nozzles, under atmospheric conditions and pressures up to 115 psi.

nozzle performance PDI measurement

Quench Flow Optimization

A crucial aspect of the gasifier flow is at the transition from the reactor to the quench tube. In this relatively small region, complex flow interactions include multiphase flow with heat transfer, and density and phase change.

Through high-speed imaging, we are able to observe flow patterns and interactions between the gas and coolant in these regions. Advanced instrumentation allows measurement of liquid flux and droplet flow field.

Together, these data are helping our clients to identify causes of flow maldistribution and optimize quench and therefore gasification performance.