Custom Research Equipment – Seaweed Tanks

Posted on June 17, 2021 Instrumentation & Equipment Design

This post was originally published in two parts which have been combined below.

Part 1

When researchers at The University of British Columbia set out to study the impact of climatechange on the growth of ocean vegetation, they contacted Coanda to develop a suitable piece of equipment.

These tanks, dubbed Climate Controlled Growth Flumes, would need to deliver the optimal yet adjustable environment in which to perform the study. More info: bit.ly/CoandaUBC

Our engineering and instrumentation teams developed a total of six units fulfilling a long list of stringent requirements:

• Oscillating flow (direction reversal) at short intervals to mimic wave action

• Well-conditioned flow in both directions

• Flow measurement for flow rate control

• A temperature control system

• Extensive material compatibility and longevity due to the harsh salt water environment

• Fluid sterilization and cleaning to minimize unwanted biological growth during multi month experiment durations

• Robust components and assembly to handle long term continuous operation.

Additionally, the apparatus needed web-enabled maintenance capabilities to monitor long term experiments. To implement and control a system this complex, Coanda’s instrumentation and software team developed a custom solution. Tune in to our next post to find out more.

Part 2

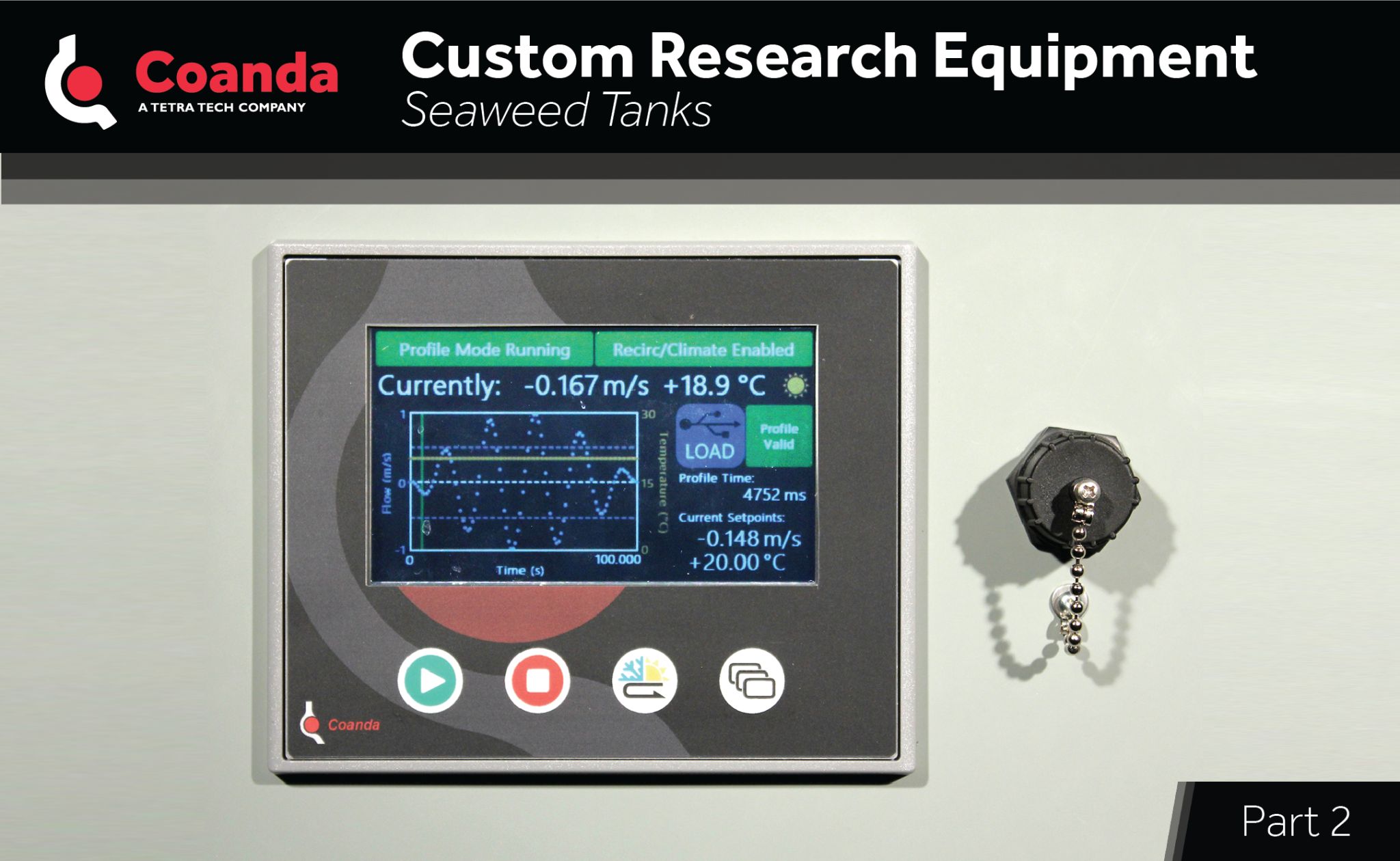

The climate-controlled growth flumes allow the researcher to control the flow and temperature profile the seaweed experiences, allowing realistic recreations of different ocean environments. To accomplish this, Coanda developed a user interface which allows conditions to be set through a touchscreen. Complicated profiles can also be generated by computer and transferred by USB drive.

The system is designed to be failsafe. For instance, in the event of a chiller failure, the chiller and non-essential components automatically power down, to prevent overheating of the tank, but water circulation is continued to maintain gas exchange; during the night, when photosynthesis is not taking place, the seaweed needs oxygen. The chiller can be repaired and put back into service without damage to the seaweed.

The impeller is driven by a servo that would normally be found driving a robot in an automotive assembly line. The servo can continuously and accurately operate at low speeds without overheating, constantly reverse direction and deliver high power.

All told, the systems give the researcher an industrially robust research platform with an ease-of-use normally seen in consumer electronics.