Mining – Screening Systems

Posted on August 24, 2021 Mining

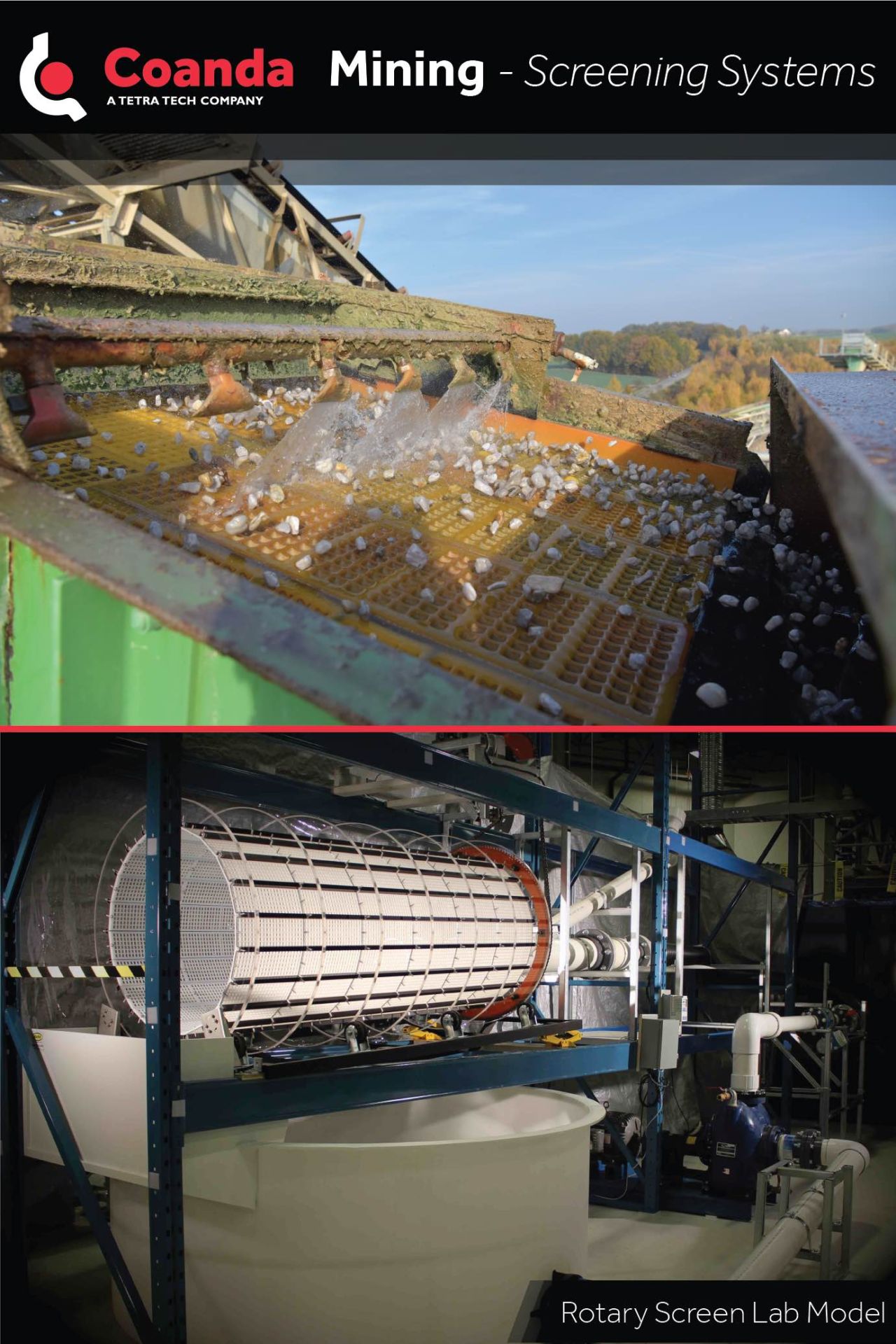

Screening systems are used in mining applications to remove oversize material from streams of crushed ore and/or slurries. Wet screening systems typically feature stationary flat, vibrating or rotating screen configurations.

Screen design and performance face several challenges:

· Distribution: Feed often comes from a pipe or mix box and must be spread out across the entire area of the screen to maximize separation performance.

· Wear: Minimizing or distributing wear across the screen area minimizes repairs and downtime. Rotary screens naturally distribute wear more evenly around their circumference at the cost of increased mechanical complexity.

· Short-circuiting: A poorly designed screen system may have crossflow velocities that cause liquid and finer material to skip across holes and follow the oversize reject material resulting in loss of valuable product.

Coanda has conducted several projects in mining and related industries to design better screen systems for specific applications. We use a combination of physical scale modelling with analog materials and computational fluid dynamics (CFD) to address issues with the design of screen holes and structure as well as feed systems.