This post was originally published in two parts which have been combined below

Part 1

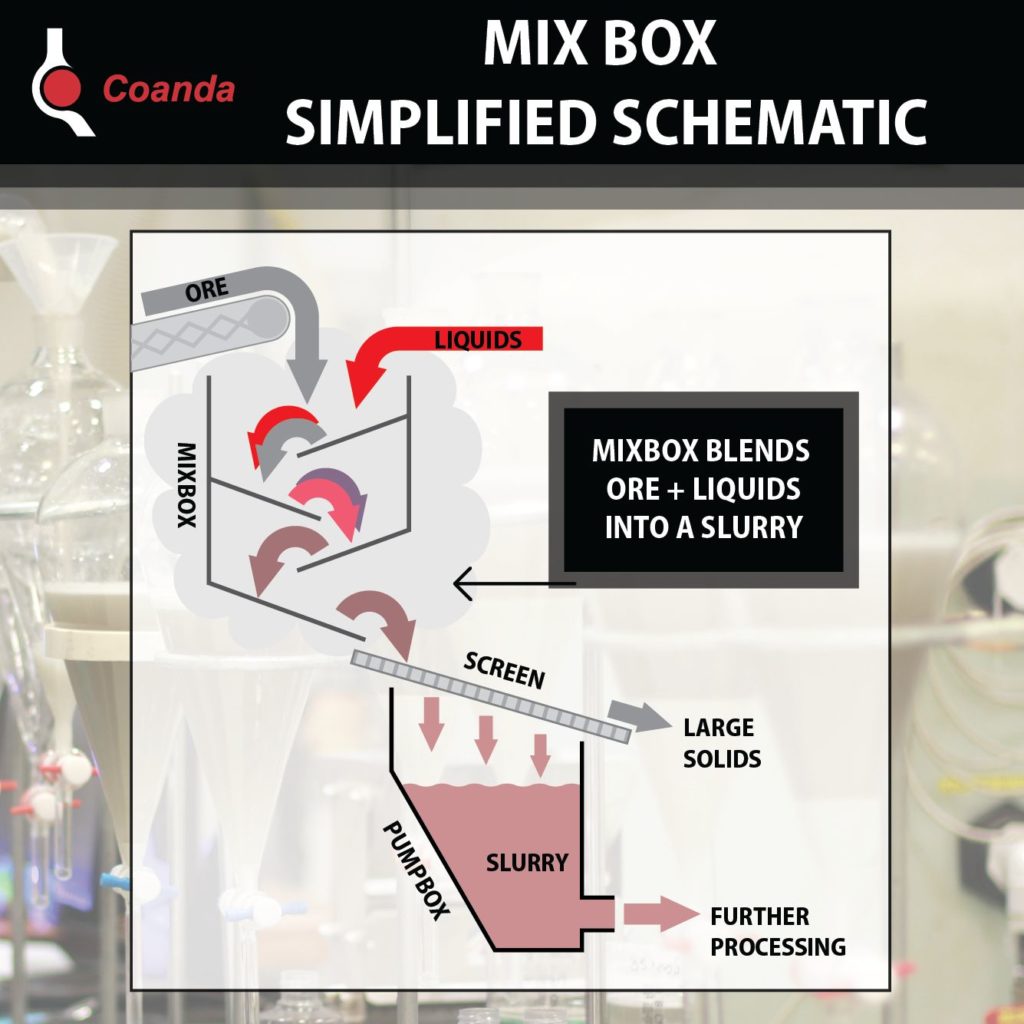

Mix boxes for ore slurrification must effectively blend dry ore and water with aggressive impacts to induce lump breakup. The challenges in these designs include minimizing capital and operating costs while maximizing reliability and performance with varying feed compositions and flow rates.

In many mix box designs, gravity is the primary source of energy input. Solids input is usually at the top of the box. Liquid streams are primarily added at the top of the box, but are often supplemented with additional injection points lower down to meet particular process needs. Internals are designed to break lumps and mix solids and liquid in a minimum vertical distance. In some applications, screens (vibrating or rotating) are placed immediately downstream of mix boxes to remove oversize material. The distribution of slurry at the outlet of the mix box is important to ensure even wear and optimal performance of those screens.

Coanda uses a combination of physical scaled models and computational simulation techniques to develop, test, and optimize mix box designs for our clients’ specific applications. Physical models are constructed with transparent sections to allow direct observation and give important insights into flow within the mix boxes that is difficult or impossible to obtain in a commercial or pilot operation. Computational models provide a different insight into the performance and are validated against the physical models and/or client commercial performance data where available.

Part 2

Coanda has also worked closely with large mining clients for both new facilities and to optimize existing designs in pre-existing installations. These studies have focused on a number of objectives:

• Increasing lump break-up, leading to better mixing performance

• Improving outflow distribution to reduce downstream vibrating screen wear

• Assessing rate of wear for internal impact surfaces

• Minimizing the height and overall mix-box size and capital cost to meet performance targets.

• Achieving consistent high performance with highly variable feed rates and compositions.

These elements often work in conjunction with each other, with improvements in one often leading to gains in the others, ultimately lengthening the mean time between failure (MTBF) and associated costly plant shutdowns necessary to replace worn components.

Coanda’s modelling approaches allow our clients to evaluate the effectiveness of proposed mix-box geometry and operating changes in a cost-effective manner prior to implementation in a commercial ore processing train. This minimizes the risks associated with under-performing equipment from an operational, profit, and regulatory perspective.