Nuclear Power

Posted on September 12, 2023 Cleantech

This post was originally published in two parts which have been combined below.

Part 1

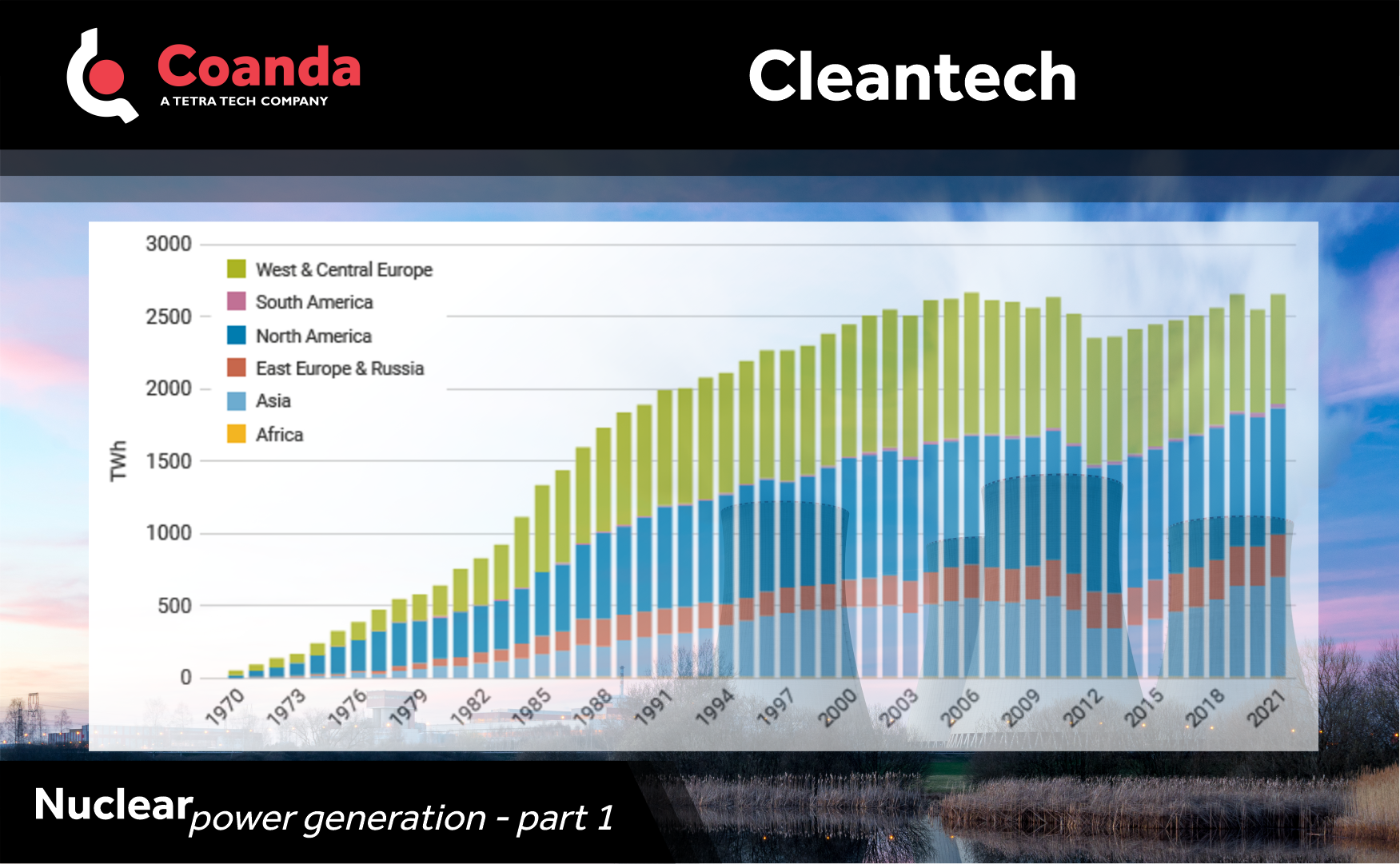

Nuclear power is the second-largest source of low-carbon electricity today, trailing only hydroelectricity. With 452 operating reactors providing 2700 TWh of electricity in 2022, 10% of global electricity supply is provided by nuclear fission. It is even more prevalent in developed economies, where nuclear power is the largest source of low-carbon electricity, providing 18% of supply, with certain countries relying on nuclear power for most of their needs, (France 62%, Slovakia 59%). However, nuclear power is on the decline globally, with decommissioning of reactors eclipsing the capacity of new construction.

Nuclear power has avoided approximately 55 Gt of carbon dioxide emissions over the past 50 years, equal to nearly 2 years of current global energy-related CO2 emissions. While it is unclear whether this figure accounts for carbon emitted during plant construction and uranium mining operations, this still represents a significant benefit from the point of view of reduced CO2 emissions. However, this is largely overshadowed by the impacts of contamination from spent fuel and numerous nuclear accidents. Once touted as the clean energy solution of the future, the reputation of nuclear power has been severely, and possibly irreparably damaged by the terrible disasters of Chornobyl and Fukushima.

In our next post we will discuss some of the reasons for this decline, and the role nuclear energy may play in transitioning to a low-carbon economy.

Part 2

In our previous post, we highlighted some of the benefits and global production capacity of nuclear fission power. The use of nuclear power is on the decline however, and today we explore some of those reasons.

The global impact of the nuclear disasters of the past quarter century have stained nuclear power’s reputation. Even if safety measures could eliminate future failures, spent fuel causes sites to be contaminated for decades or centuries. Combined with increasing costs, competition from emerging technologies such as wind and solar power, and legitimate concerns over nuclear arms proliferation, it is easy to see why nuclear power has fallen out of favour in many parts of the world.

Despite the decline in construction of new plants in most of the world outside of China and Russia, maintaining existing nuclear capacity remains an important means of reducing CO2 emissions during the transition to cleaner energy sources. However, in the world’s most advanced economies, the average age of reactors is now 35 years, and many reactors are reaching the end of their license. If no action is taken, nearly a quarter of existing nuclear capacity in industrialized countries is scheduled to close by 2028. The cost of extending the operating life of these facilities is much less than that of new construction, and, depending on the condition of the site, often favourable compared to replacement with new clean-energy facilities such as wind or PV solar generators. Ensuring that these facilities can be operated safely for decades to come requires significant capital investment, however. The estimated cost of extending the operational life of 1 GW of nuclear capacity for at least 10 years starts at US$500 million for a site in good condition.