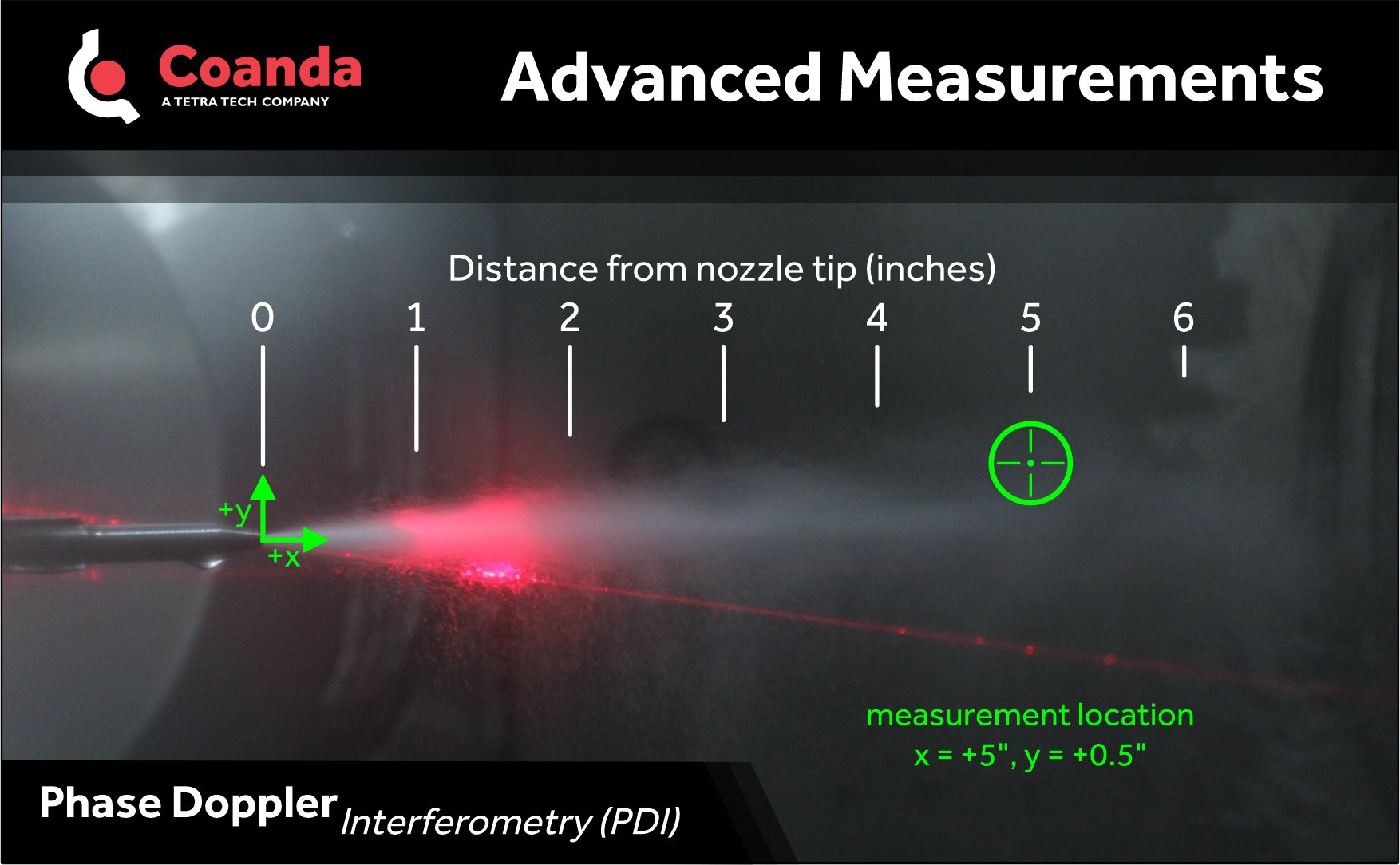

Spray Nozzle Characterization with Phase Doppler Interferometry (PDI)

Posted on June 16, 2022 Nozzles Jets Sprays

We use Phase Doppler Interferometry (PDI) to characterize nozzle sprays. PDI is a nonintrusive laser-based measurement technique, which uses laser-Doppler anemometry to simultaneously measure the diameter, velocity, and volume flux of individual droplets.

The instrument consists of separate transmitter and receiver units, positioned such that they focus on the same point in space. Two pairs of laser beams are focused using a transmitter lens and made to intersect at a shallow angle, forming the measurement volume.

Where the two laser beams intersect, an interference pattern of alternating light and dark bands is formed. This pattern would be stationary if the beams had the same frequency, but an ultrasonic diffraction grating is used to create a frequency shift between the beams, which causes the interference pattern to move. A stationary droplet will appear to flash as the interference pattern moves over it. If the droplet is moving with or against the interference pattern, the flashing will be slower or faster (Doppler effect).

Light scattered by objects passing through the measurement volume is collected by a receiver lens and focused onto a photodetector. The component of the object’s velocity in the plane of each laser beam pair, and perpendicular to the pair’s axis, is determined from the frequency shift of flashes. The object’s size can be determined from the phase-shift between signals received at photodetectors separated by a known distance.

By focusing two pairs of different coloured beams on the same point, but oriented in different planes, the velocity can be resolved in two dimensions perpendicular to the common beam axis.