Process Engineering – Simulator

Posted on March 8, 2022 Process Engineering

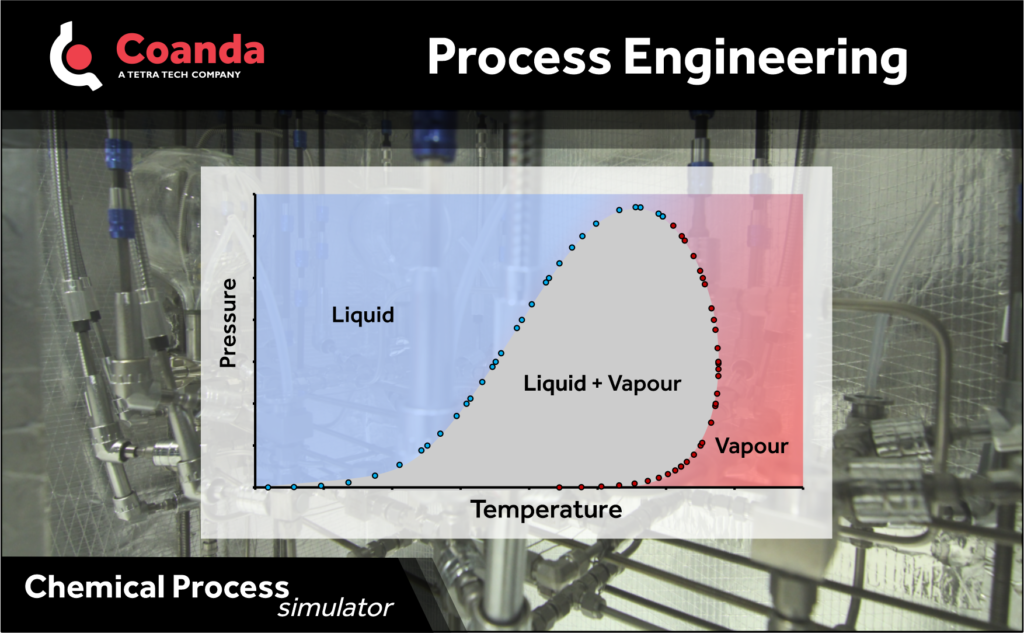

When modeling a process, understanding the state of the system may improve knowledge to tackle problems and optimize for maximum process performance.

Is the process in a liquid state? Is the process at a vapour state? Or a multiphase state?

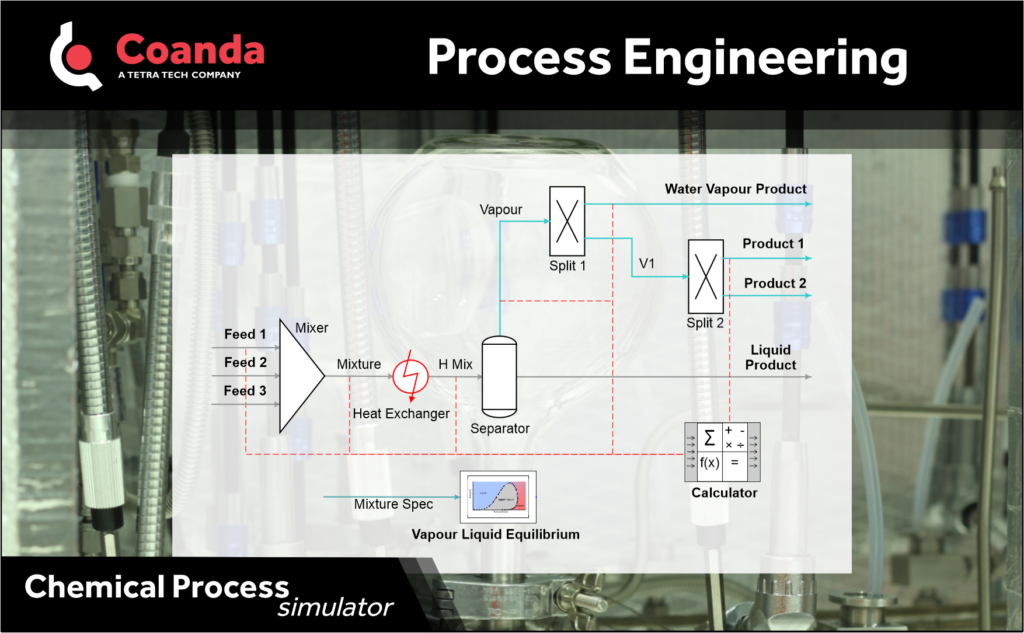

We use chemical process simulators to model thermodynamic behaviors of processes, pilot plants, and lab scale systems. Equations of state and activity coefficient models are the mathematical engines used to evaluate mass and energy balances in such simulators. Physicochemical properties of pure components and their mixtures can be predicted with high approximation with the correct property package. Understanding the process environment conditions, the types of mixtures present (polar, non-polar, etc.), and whether the system is ideal or not, is critical to providing quality results. Such results help guide client decisions on processes, pilots, and lab experimental systems.