Particle Size Distribution Measurements

Posted on February 15, 2024 Instrumentation & Equipment Design

Precise particle size control is paramount in systems like fluidized beds, where the dynamic interplay between the solid particles and the gas phase significantly influences overall performance. First and foremost, the reaction kinetics are closely linked to average particle size, which has a direct impact on total surface area and bed hydrodynamics. Additionally, in processes such as fluid coking and fluid catalytic cracking where multiple phases can coexist, maintaining optimal particle size ensures uniform fluidization dynamics, preventing issues like channeling, short-circuiting, or agglomeration.

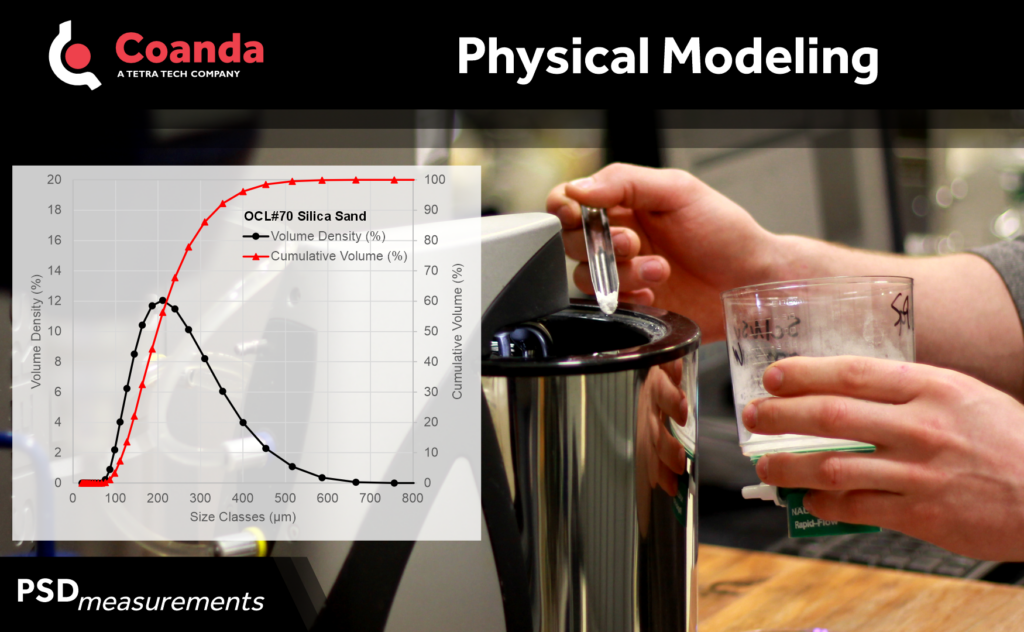

Accurate particle size measurements are also critical when scaling up multi-phase processes to larger industrial applications. Scaled physical models, such as those operating at Coanda, serve as invaluable tools for simulating real-world conditions and optimizing operational parameters at commercial scales. In these models, the reliability of results hinges on the precision of particle size measurements, as imprecise data can lead to discrepancies in predicted fluidization behavior, heat transfer characteristics, and overall process dynamics. Therefore, obtaining accurate and representative particle size measurements in our physical models is essential for ensuring that similitude is maintained between the laboratory-scale apparatus and the industrial-scale process.

One of Coanda’s most widely used instruments for particle size measurements is the Malvern Mastersizer 3000, a laser diffraction-based particle analyzer. It operates by projecting a laser beam through a representative sample of particles and measuring the angles of scattered light. This data is then used to generate a particle size distribution (PSD), thereby providing insights into the range and distribution of particle sizes within the sample. Distribution average parameters output by the instrument include the Sauter mean diameter (SMD), which is a representative surface area weighted diameter of the entire PSD. The SMD is often used in processes where surface phenomena such as mass or heat transfer kinetics are important.