fundamental processes

Mixing, reaction and separation are the three elemental steps of most chemical processes. Efficient reaction and separation depend largely on a foundation of good mixing. But what does good mixing really mean? The idea of “well mixed” is easily discarded as being intuitively obvious. However, real industrial practices pose a real challenge to the obvious well mixed concept out there and even the smallest contributions on mixing insight on any particular industrial process have a major impact on process yield, productivity and sustainability across a wide range of industries.

Key Focus

Developing this process mixing insight has been central competency for Coanda for over 20 years, advancing crucial technology developments in the area of mixing for a wide range of industries including Polymer manufacturing, Mining, Petroleum, Biotechnolgy, Pulp and paper, Oil Sands etc.

The study and development of industrially relevant mixing technologies at Coanda is supported by a complete suite of tools including physical modelling, dimensional analysis, computational modelling, and advanced rheological and experimental measurements.

dye injection to highlight mixing cavern

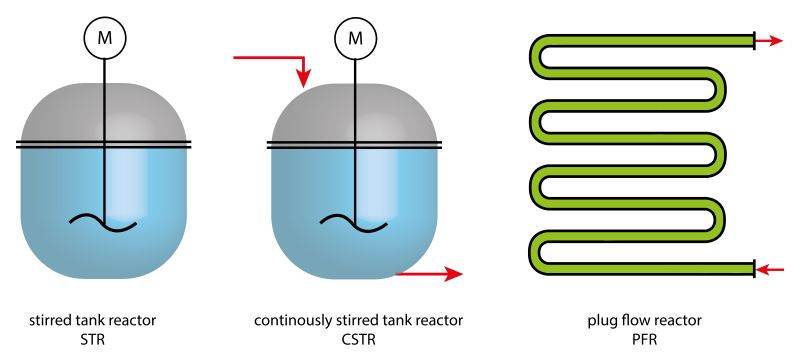

continuous stirred tank reactor (CSTR) model

Advanced Experimental Methods for Mixing Measurements

Shown here is a laboratory simulation performed at Coanda to study mixing in a chemical reactor vessel. 2D Laser-induced Fluorescence (LIF) was used to quantify the scalar concentration field following a pulse injection.

Additional experimental measurements on the study of mixing processes include Electrical Process Tomography, Particle Vision Microscopy (PVM), Focused beam Reflectance measurements (FBRM), 2D resolved spacial conductivity measurements etc.

jet induced mixing LIF measurement

Mixing non-Newtonian Fluids and Slurries

Numerous projects at Coanda are focused on progressing mixing technologies able to address complex non-Newtonian characteristics underlying pivotal chemical reactions and separation processes in the chemical and petrochemical industries.

Coanda has been central on the development of mixing expertise under extreme conditions. Key examples include the mixing and flocculation of concentrated tailings suspensions in the Oil Sands industries.