Widespread Use

Nozzles are widely utilized in industry to inject fluids, both single and multi-phase, into a process vessel or pipe. They are commonly used to control the rate, direction and shape of the injected flow, and are typically used to accelerate a fluid to increase local mixing and mass/heat transfer within a process.

Broad Categorization

The simplest kind of nozzle is a single orifice type that is used to inject a jet of a fluid into another. Nozzles can be grouped into two categories, Jets or Sprays:

- Injections of a gas into a gas, a gas into a liquid, or a liquid into a liquid are defined as jets.

- injections of liquid into a gas, where significant droplet formation is anticipated, are termed as sprays.

gas / liquid mixture entering a nozzle

Finite Element Analysis (FEA) on a 3-way nozzle

Fundamental Principles

Nozzles are designed to generate droplets using two basic principles:

- The first principle relies on shear and/or impact, where the liquid stream is atomised by being accelerated through an orifice and is sometimes also directed towards an impact plate for further atomisation.

- Such nozzles are generally simple, single-phase designs operating at relatively high pressure, and are the most commonly used nozzle type in industries such as:

- agriculture,

- power generation,

- automotive,

- oil and gas,

- Pharmaceutical, etc.

- The second design principle prevalent in industry for liquid atomisation is the effervescent nozzle, where the liquid is mixed with a gas well upstream of the nozzle orifice. As the gas-liquid mixture exits the nozzle, the gas experiences a pressure letdown, causing a rapid expansion and a relatively high-velocity region near the nozzle tip. This rapid expansion of gas effectively rips the liquid stream apart and is a very effective means of droplet generation.

- This type of nozzle is commonly used in industries where relatively high flow rates of liquid are atomised using relatively low pressures (typically << 500 psi), and where process steam or compressed air are available for atomisation. Steam or air requirements are generally less than 10% on a mass basis.

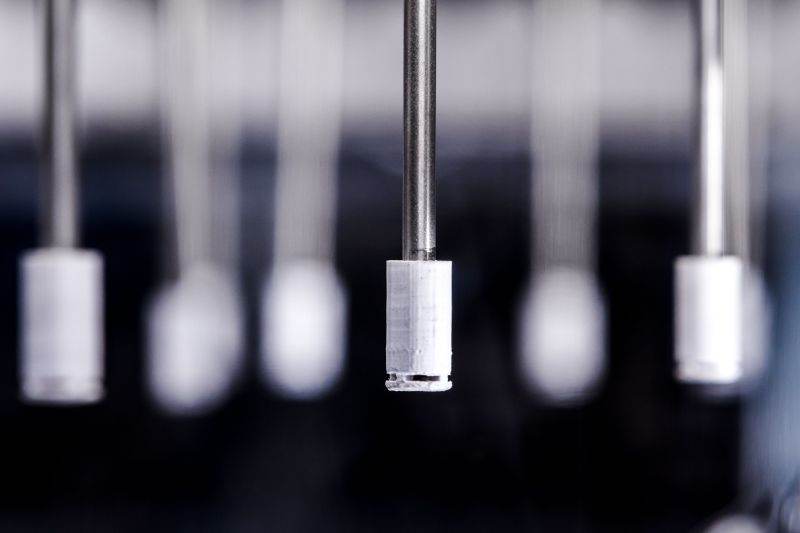

3D printed inlet nozzles

Coanda Expertise

Coanda has worked on a wide range of nozzle development and optimisation projects, across a broad range of processes, including fluid coking, polymerisation, distillation, gravity separation, and much more.

We leverage our experience, and a widely accepted nozzle scaling strategy using dimensional analysis, to prescribe the nozzle operating conditions in the laboratory, typically employing benign fluid analogues such as air and water that are safe and cost-effective to operate.

Nozzle performance metrics are collected using a wide variety of measurement techniques, including flow visualisation, and quantitative measurements such as distributions of droplet size, velocity, and liquid flux.

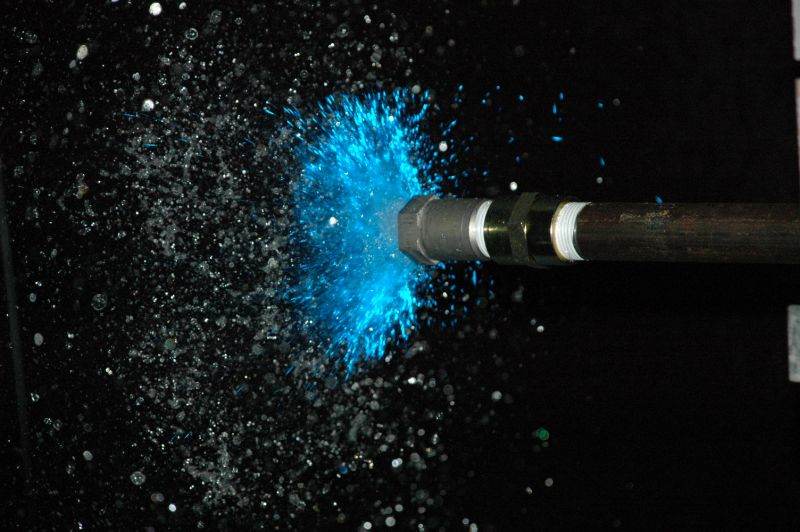

spray nozzle evaluation

Dedicated spray testing facility

Coanda has an on-site custom built spray facility that is dedicated to the testing of nozzles. The spray facility includes instruments such as an Artium Phase Doppler Interferometer (PDI) that is used to measure droplet size, velocity and flux distributions, and several Phantom high-speed cameras including two VEO710 cameras capable of obtaining up to 7,400 frames per second at a resolution of 1280×800 pixels.