Developing New Processes

The development of a new process typically requires the scale-up of design criteria that have been optimized at reduced scale. The general design progression of a new process begins in the laboratory as a bench scale model, followed by a larger pilot plant, and then by a larger yet demonstration unit, which finally leads to the design and construction of a full scale plant operation.

Increasing production rates to commercially viable levels often involves changes of several orders of magnitude in both size and costs as compared to the initial bench scale concept so it is important to design the commercial process to maximize performance, efficiency and product quality.

scaled feedwell inlet

process pilot reactor

Understanding Key Parameters

Scaling up any industrial process involves understanding the key parameters that determine the performance of that process and the quality and rate of production. Bench scale or pilot scale testing occurs in systems with short timescales, small volumes, short residence times, and with more easily controlled and tuned input and output parameters.

The geometric configurations and even whether it is a batch or continuous process may be quite different between the small-scale test system and a commercially viable unit.

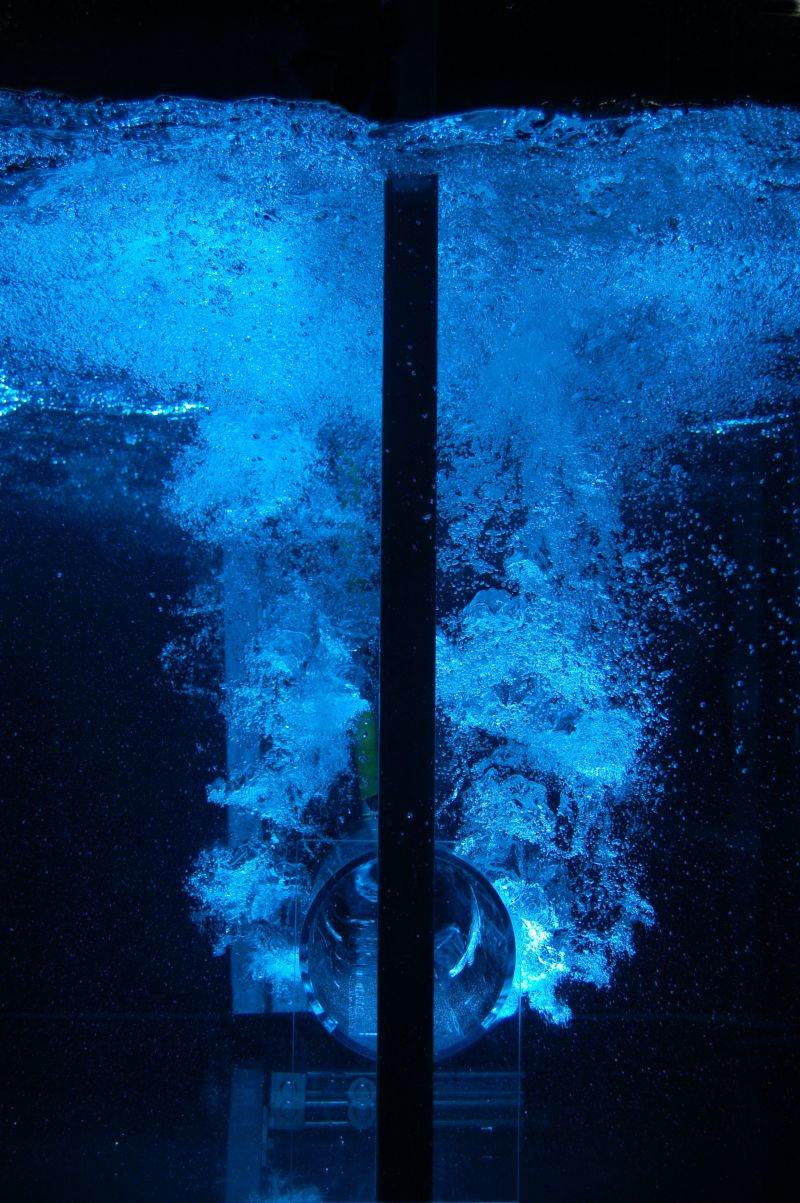

gas distribution sparger model

Coanda Expertise

Coanda has the expertise to help our clients accurately characterize and measure the performance of the small-scale units and determine the most important process parameters. Some of the methods of generating this understanding are dimensional analysis, physical and computational modeling.

The proposed larger scale units can be examined and compared in the same context using the same techniques as discussed above and highlight the key differences that might be expected to affect the process performance. Large scale systems almost inevitably involve higher flow velocities, higher levels of turbulence, longer residence times and slower response to changes as compared to the small scale tests.

Scale-up isn’t About Just Making Things Bigger

Geometric configurations that are practical and even required at the pilot scale may not be practical to enlarge to commercial production. If scale-up were simply about making something bigger we could simply use a photocopier to enlarge the drawings of the bench system.

Sometimes there must be an iterative procedure whereby scale-down will be used to evaluate the importance of particular operating parameters or procedures at the small scale so we understand how to factor that into a larger scale system. For a simple example, if a process requires good mixing of two materials that is often trivial on the bench, just mix it a little longer or with a little more energy.

Evaluating Performance

At commercial scale it is critically important to determine exactly how much mixing is required or you could significantly over or under size your equipment, increase operating costs or actually destroy product quality. Proper planning of bench or pilot scale tests can be used to evaluate this performance range and help reduce the uncertainty in the successful commercial outcome.