Hydrogen Technology Development

Posted on October 24, 2023 Technology Development Support

This post was originally published in two parts which have been combined below.

Part 1

In recent years, there has been a growing interest in hydrogen production driven by global shifts towards cleaner and more sustainable energy sources. Hydrogen, with its potential as a versatile and environmentally friendly fuel, holds the promise of reducing carbon emissions in various industries, such as transportation, energy generation, and manufacturing. As a result, researchers and companies are investing in innovative technologies and methods to scale up hydrogen production.

When it comes to the development of new hydrogen generation processes, the role of cold flow modeling in de-risking the design is significant as a cost-effective strategy by helping to avoid mistakes and design changes during later stages of development. Cold flow modeling is often used to address knowledge gaps and potential issues early, generally in the technology development stage, as it provides a systematic approach to validate and optimize the design.

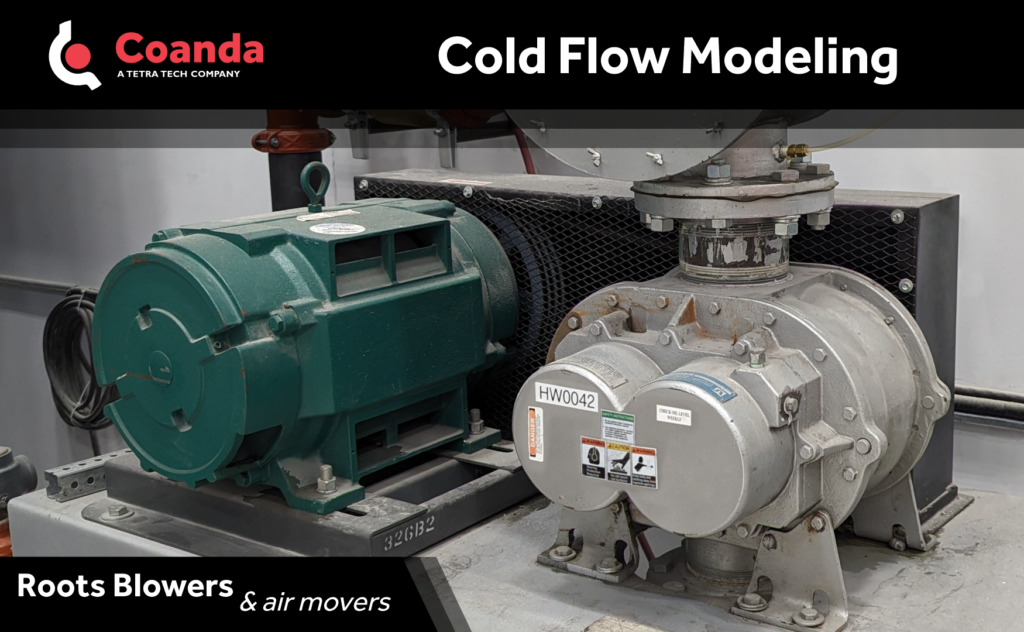

At Coanda, we have the knowledge and expertise to design and build cold flow models that provide close similitude to the commercial process at reduced scale and often using analogue fluids. For hydrogen generation processes where low gas densities are involved, we employ vacuum pumps and blowers to produce low-density gas within experimental equipment, effectively simulating the conditions at a fraction of the cost. Our facilities include a variety of vacuum pumps and blowers, with sizes ranging from < 1 hp to 150 hp and designs generally falling into the roots blower and the rotary vane types.

Tune into our next post, where we explore roots blowers and other air movers.

Part 2

In our previous post we introduced the role of cold flow modeling in Hydrogen technology development and the part air movers often play in such experimental studies. Today we explore some of the equipment options.

Roots blowers generally consist of two lobed rotors that rotate in opposite directions within a housing. As the rotors turn, they trap and transport gas from the inlet to the outlet. These blowers are widely used for applications requiring high gas flow rates at relatively low vacuum levels making them well-suited for apparatus such as fluidized beds and pneumatic conveying systems. Roots blowers feature a reliable and robust construction and can handle wet gases and solids, have low maintenance requirements, and are suitable for continuous operation. At Coanda, our largest roots blower can achieve vacuum pressures up to -9 psig at inlet flow rates exceeding 3800 CFM.

Rotary vane pumps employ a series of sliding vanes mounted on a rotor within a cylindrical chamber. As the rotor spins, the vanes create chambers of varying size, causing gas to be drawn in, compressed, and expelled through the outlet. These pumps are commonly used in applications requiring moderate to high vacuum levels such as vacuum distillation, filtration, and gas sampling and tracing applications. They are compact and relatively lightweight. They are known for their low vibration and noise levels, making them suitable for laboratory settings.

In summary, we use vacuum pumps and blowers with cold flow models at reduced scale to closely mimic commercial conditions of hydrogen generation equipment. Our scaling expertise and physical modeling infrastructure is often leveraged by our clients de-risk novel hydrogen generation designs and technologies.