Thermocouples

Posted on March 2, 2023 Instrumentation & Equipment Design

This post was originally published in two parts which have been combined below.

Part 1

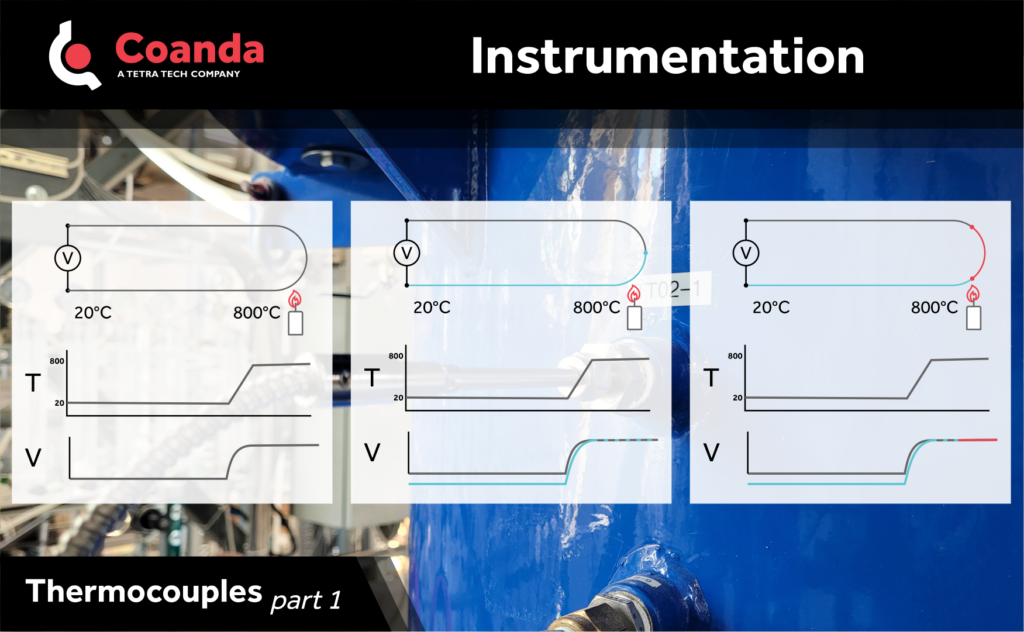

A thermocouple is simply a junction between two wires made of different metals. The Seebeck Effect is often presented as a voltage being produced by the contact by the two dissimilar metals, but that’s a bit inaccurate.

Fundamentally, a thermal gradient on a conductor creates a voltage gradient along the conductor. The relationship between the thermal gradient and voltage gradient is non-linear and different for each metal. The mechanism for this relationship is well understood but requires too much solid-state physics background to cover here.

Heating the middle of a single wire and measuring the voltage at either end will result in a measurement of zero Volts. Whatever voltage was produced by the gradient between one end of the wire and hot portion is cancelled out exactly by the gradient between hot portion and the other end.

In a thermocouple, the relationship between the thermal gradients and voltage gradients are different, so they don’t exactly cancel. This creates a small but measurable voltage.

It’s fundamentally not the junction itself that makes the voltage, but the thermal gradients in dissimilar metals creating different voltage gradients. If I add a bunch of different junctions in an area of constant temperature, it has no effect on the voltage, as there are no thermal gradients to create voltage gradients.

To be concluded in our next post…

Part 2

In our previous post we introduced the concept behind thermocouples.

A thermocouple measurement is fundamentally a voltage measurement. If the relationship between temperature and voltage of both metals is known, and the temperature of the free ends of the thermocouple are known, the junction temperature can be determined. Every thermocouple measurement device must therefore have a built-in direct temperature measurement, such as a thermistor, RTD or bandgap reference.

Thermocouple voltages are very small, typically on the order of a microvolt per degree Celsius. The thermocouple evaluation electronics needs to be able to measure with microvolt accuracy while rejecting the electrical noise typical of industrial environments, and they need an internal temperature measurement by some other means.

An obvious question might be: why use a thermocouple at all instead of just using whatever the thermocouple evaluation electronics are using to measure temperature internally? There are often good answers. If the thermocouple is measuring flame temperature in a furnace, it’s the only option that will survive. Chemical compatibility or space constraints can make thermocouples the best option.

RTDs, semiconductor bandgap measurements and thermistors all can be much more accurate than the best that can be achieved by a thermocouple, with a lower installed cost. While thermocouple wire is almost free, the evaluation is relatively expensive.