Bubbles Matter

Posted on March 22, 2022 Instrumentation & Equipment Design

This post was originally published in four parts which have been combined below.

Part 1

Bubbles matter. In mining, bubbles separate the ore from the tailings during froth separation. Bubbles in a water- or slurry-filled pipe can cause pipe corrosion. In reactors, the size and distribution of bubbles can limit reaction rates. Bubbles cause pump wear.

Fluidized beds can have large bubbles, which transport unreacted material through the bed without interaction having taken place. Bubbles forming through chemical or biological action in tailings can rise to the surface and disrupt closure strategy.

There isn’t a standard method for quantifying bubbles as the size and environment often limit available approaches. Quantifying trace quantities of small bubbles in a clear fluid and large bubbles in a fluidized bed are both challenges, but that’s where the similarity ends. Coanda has used a wide range of techniques to measure bubbles in a variety of contexts.

Over the next 3 posts, we’ll cover Coanda’s in-house developments for bubble measurement and touch on some of the commercially available instruments we use.

Part 2

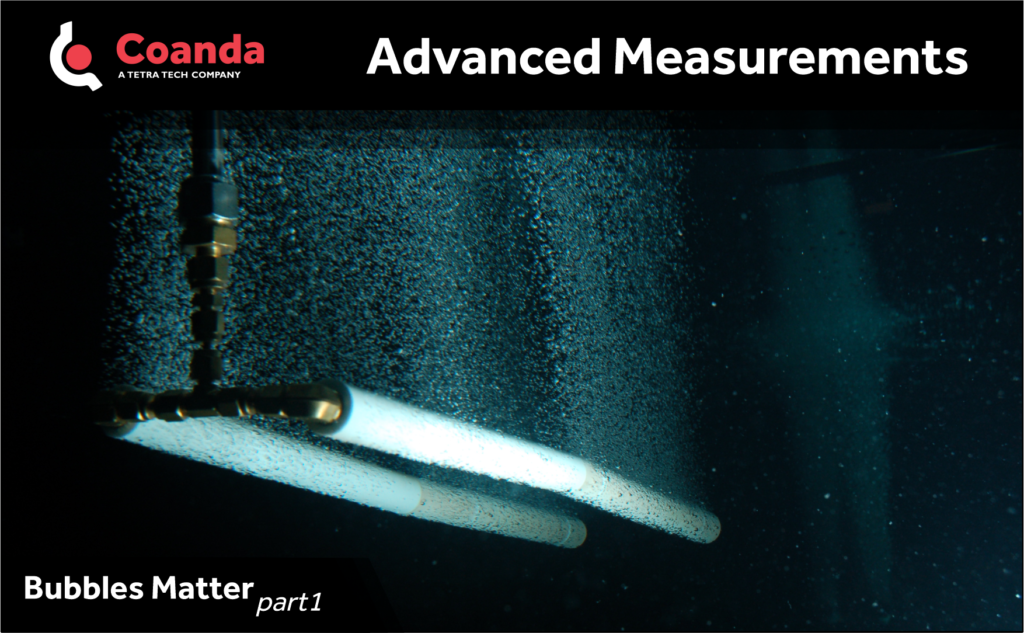

Coanda uses two conductivity-based techniques to get total bubble volume and point measurements of bubble distributions.

The bulk electrical conductivity of water decreases as bubbles are added. Bubbles cause the current to flow in a more tortuous path, which result in a greater change in conductivity than implied by taking its volumetric average. Measuring the conductivity between two electrodes gives inconsistent results, partially because of an excessive sensitivity to bubbles near the electrodes where the field lines are concentrated, and partially because of electrochemical effects. By using four electrodes, two that drive current and two that sense voltage, we take the voltage measurement away from any concentrated field and get a representative conductivity.

Rather than removing the sensitivity to the zone around the electrodes, we can amplify it by using a direct measurement from tiny electrodes. This provides almost no information about bulk concentration of bubbles but does produce a strong signal as bubbles go over the electrode. If the speed of the bubbles is known, the size can be found from the duration of the conductivity drop.

Part 3

Last time we looked at electrical means of characterizing bubbles.

Those techniques are great for bubbles in a fluid with nothing else, but they can fail if the fluid isn’t water or if too much of the apparatus is conductive.

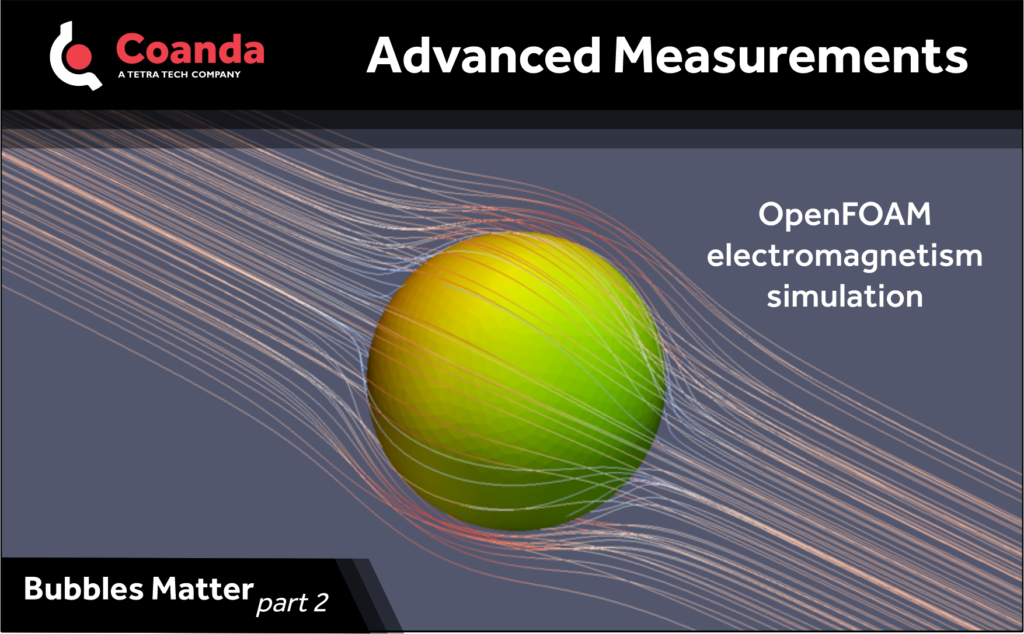

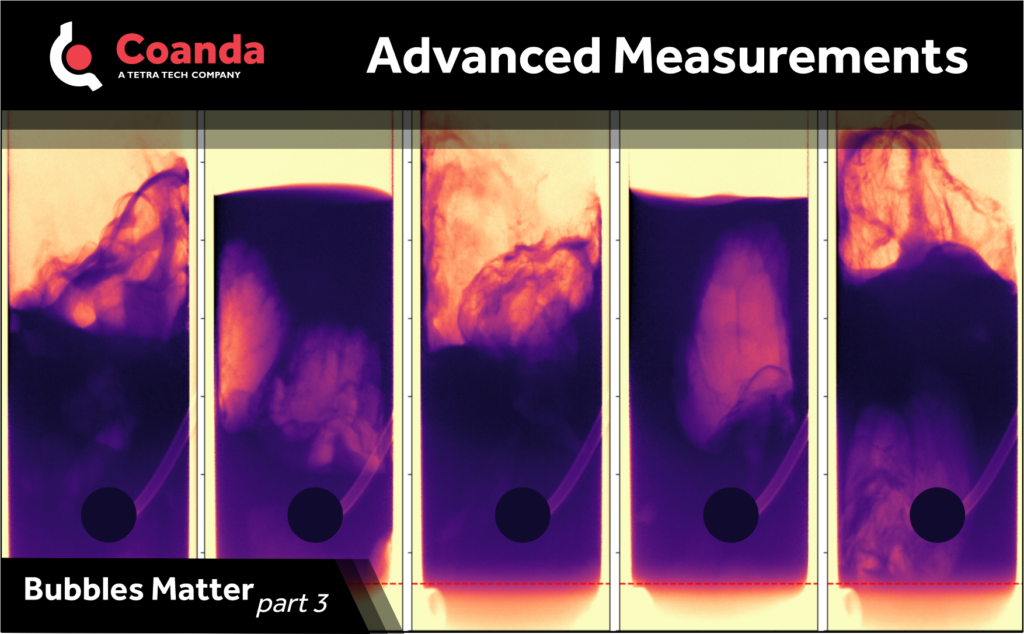

X-ray imaging allows for completely non-intrusive measurements of bubbles in diverse materials. We highlighted our x-ray work on fluidized beds in previous posts. With yield stress materials and slowly-evolving bubbles, a full tomography can be performed by imaging from a variety of angles. Bubbles forming due to biological action in saturated soils is a practical example where tomography is applicable. While X-ray imaging may seem like a magic bullet, there are inherent limitations; since the signal drops exponentially with the amount of material the x-ray has to go through, there are practical limitations to the size of the domain being imaged. The requirement for heavy lead shielding often makes X-ray the right choice only when nothing else will do.

Where we have visual access and a clear fluid, we’ll use machine vision to extract quantitative data, like size distribution, concentration and velocity directly from captured video.

Part 4

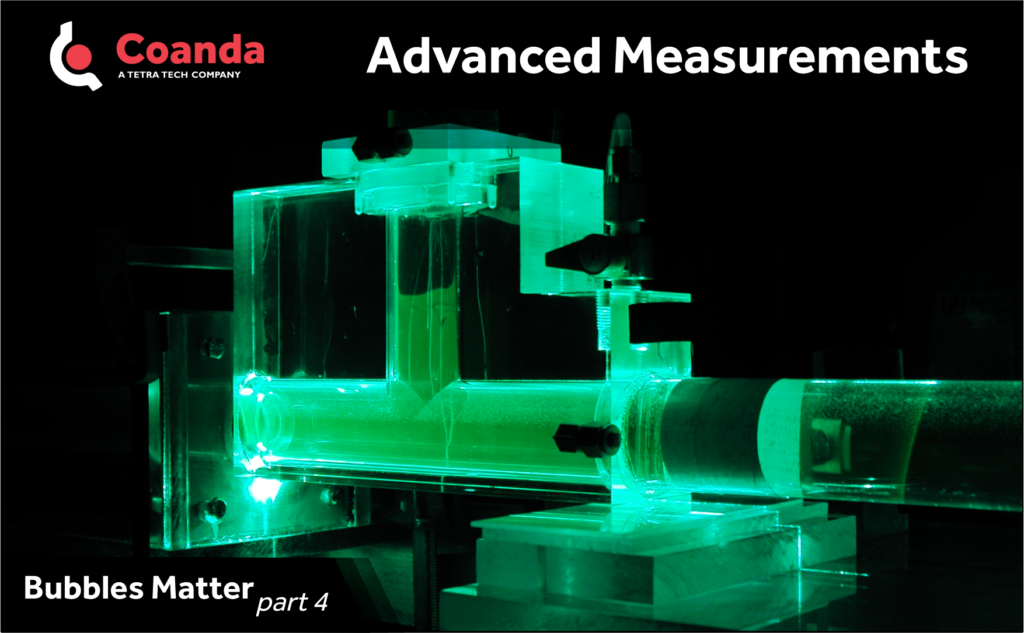

We’ve gone through our electrical, X-ray and machine vision techniques for bubble measurement. Here we briefly touch on a few commercial solutions we use.

In addition to our in-house developments, Coanda uses a number of turn-key solutions for bubble measurements. We have several laser-diffraction based instruments (including PDI – Phase Doppler Interferometry) which can return a particle size distribution. These can be adapted for bubble measurement if the bubbles are sufficiently small. Hot film anemometers can detect bubbles in very fast-moving flow.

What’s more important than what we have done is what we can do. Every custom solution we have developed overcomes the lack of commercially available solutions to meet the exact needs of the challenge at hand. If you have a scenario where none of the highlighted techniques can meet your needs, get in touch and we’ll get to work on adding another solution to the list.